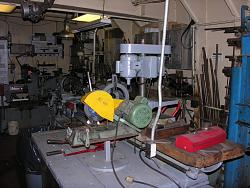

WWII hand-powered Paxton Mitchell lathe from a Liberty ship.

Description:

$300 from HarryEpstein.com: https://www.harryepstein.com/index.p...tal-lathe.htmlHand Powered WWII Liberty Ship Metal Lathe made by Paxton Mitchell. These lathes were made in 1945. Came with the original paperwork. Each lathe comes with: (1) Packing Chuck for Boring 3 3/4 Packing. (1) Packing Chuck for Boring 1 5/8 Packing. (1) Spare Feed Nut. (2) Wrenches for Above. Wrenches are specific to the parts on the lathe. Weighs 154 pounds. New old stock. Never been used, but some surface rust from sitting around.

Liberty ships were the iconic American WWII ship; over 2,700 of them were produced, which I believe is the most ships ever made to a single design. Liberty ships represented the American WWII manufacturing drive that formed the war-winning trinity of: American manufacturing, Russian lives, and British intelligence. These guys:

Does anyone know more about these lathes? Why were they hand-powered? Were these intended as general use lathes, or were they made with specific tasks in mind?

Previously:

video of WWII German military helmets repurposed into colanders

Leonardo da Vinci lathe build

WWII Churchill tank converted into mine clearer

Giant hedge cutter made from WWII AEC Matador

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks