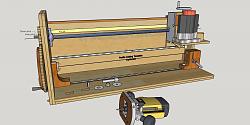

Has anyone made one of the woodsmith plans style router milling machines or anything similar? I have a design in progress and need to decide whether to use a 1 1/4HP plunge router or a 2/3HP trimmer router. This is strictly a hobby project for machining ornamental table legs etc. so speed and so on aren't necessarily a very high priority.

Col.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks