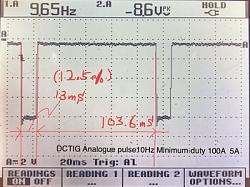

I haven't ever seen real welding wave forms either in direct current welding for steel sheets or alternative current for aluminium, magnesium.

if I was able to see them it should be informative in determining several important setting values.

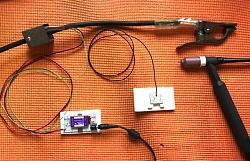

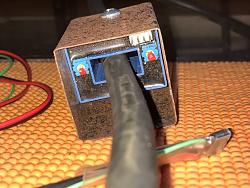

So I tried to set up a current detector added to my welder, by applying a hall effect sensor unit being sold on the market, at around the ground cable of my old analogue welder.

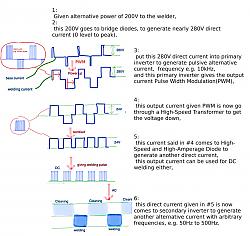

Red curves with arrows tell how welding current goes while the arc melts metal, it might sound funny to you since the arc emits out of the torch yet the current runs to the adverse direction. This is why in TIG welding the welder uses minus electrons coming out of the torch while giving heat to the spot, so the polarity of this torch should be minus and the ground (or the metal to be melted) are plus.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks