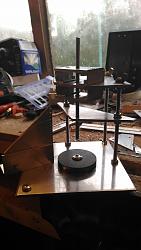

Having mayde my first vertical press drill style drill, I have now turned my mind to the very precision task of staking and tapping. very light, Very precise, pressure is required absolutely perpendicular to the work surface sometimes this needs to be a screwing force (eg tapping a watch base plate) sometimes a straight vertical push. I needed tolerances where I can adjust the head by 1/10 of a mm.

Again commercial models were outside of my funding bracket, so went back to basics to make my own.

Essentially just a series of plates, precisely drilled on my pillar drill, and then tapped to receive a threaded bar. As the bar is M6 in size - 1 turn is exactly 1mm.

When assembled I held the plates apart by nylock nuts, which also then allowed me to precisely adjust the plates to be parallel to each other and the base. the "anvil" is simply a piece circular steel, which I will drill in alignment with the pusher to hold wheel arbours etc. This can be unscrewed to make way for a pin vise.

Finally I cut a piece of bar, threaded it half way and screwed this onto the top, then soldered in place

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks