A new project to add to my watchmaker's lathe

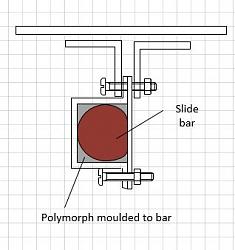

this has a D cross section slide (see pic)

Unfortunately I have not got a tool post or cross slide for this lathe - and to buy them (if you can find one) is an eye watering expense, so I've decided to make one. Now for some here, my approach may seem crude, but I'm a newbie with limited tools and skills, so I thought I'd share my approach for your thoughts and constructive (I hope) criticism - now first point is this doesn't have to be strong, but has to provide quite fine adjustments - I have chosen aluminium simply for ease of working.

My first problem is to manufacture a bracket to sit on that D-shaped slide which won't damage it, that will slide and can be clamped but that I can make easily. This also needs to provide a firm base.

To do this I'm falling back on my robotics experience and using polymorph. I don't see much discussion of it here, but in robots it's very common. For those that don't know it's a plastic with the attributes of nylon and a melting point of 700C, which means it casts very precisely and you can mould to anything. The plan is to make a box section, then to fill the intervening space with semi molten polymorph - the bar being cold and oiled will prevent it sticking to the bar and cause a really tight fit. My hope is that this should provide me with a strong fixture which when solid will slide smoothly along the bar (see pic)

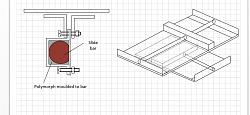

finally I intend to create 2 slides made from tapped aluminium bar which can then be moved back and forth on a bed by means of an M6 threaded bar - this should provide me with precision to 1mm per turn to the bar (see picture. these will be mounted one on the box section on the bar, and the second on the slide bar of the first at right angles.

I have yet to commence building, but these are my rather amateur sketches - your thoughts would be appreciated.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks