After the completion of the Sensitive Drill Press that I recently posted I decided that it should have its own dedicated vise.

The vise measures 1.500” wide X 1.625” tall X 4.375” Long with a 1.750” jaw opening, it’s constructed from O-1, 4140 and 1018 steels, the parts that were made from O-1 and 4140 were oil hardened, tempered and ground, although all parts were ground square.

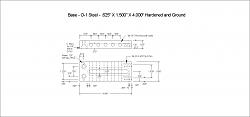

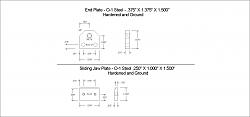

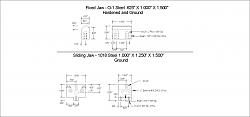

The base and fixed jaw are two separate pieces and were made from O-1 tool steel that have been hardened and ground square, the fixed jaw is secured to the base by means of two dowel pins and two socket head cap screws, after assembling these two pieces they were then reground as a unit all over to insure squarness.

The sliding jaw is made up of two pieces also, it consist of a 4140 hardened and ground steel jaw and a 1018 steel sliding block, the jaw is secured to the sliding block by two socket head cap screws, the sliding block has a tongue machined onto it that fits the groove in the base with near zero clearance, very extra attention was payed here.

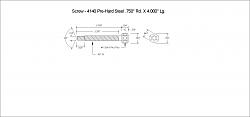

The screw was made from .750” round 4140 Pre-Hardened steel; the head of the screw has a hexagon milled onto it for the ease of turning with six .193” holes drilled thru the flats of the hex, this is so you can use a 3/16” punch or something of that nature if you need a little more torque on the screw.

Both jaws have a 3/32” X 3/32” step machined into them for holding something in the top of the vise that’s thin and or narrow, the fixed jaw also has a vertical and horizontal V-Groove machined it for holding round or square stock.

The vise is very precisely made, it can be used as a tool makers vise on the surface grinder, milling machine or just for holding something small for layout, this vise will have many uses.

Below you will find some photos of the machining processes along with some photos of the completed vise and a set of drawings for anyone who would like to make one of these vises.

As always, Thanks for looking and Happy Machining

Comments are always welcome

Doug

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks