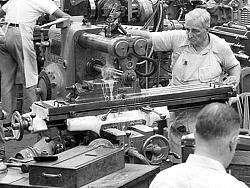

Manufacturing M3 tanks at a Chrysler plant near Detroit, Michigan. 1942.

Fullsize image: https://diqn32j8nouaz.cloudfront.net...w_fullsize.jpg

Manufacturing M3 tanks at a Chrysler plant near Detroit, Michigan. 1942.

Fullsize image: https://diqn32j8nouaz.cloudfront.net...w_fullsize.jpg

New plans added on 01/17/2025: Click here for 2,706 plans for homemade tools.

baja (Jan 20, 2019), KustomsbyKent (Jan 14, 2019), PJs (Jan 14, 2019), ranald (Jan 15, 2019), Seedtick (Jan 14, 2019), Toolmaker51 (Jan 14, 2019)

This picture is one of the reasons why I love Jon's Vintage Work Crew thread so much. Not only does it show 25 skilled professional at their tasks but vintage equipment of extraordinary quality in use. I sometimes clean these up for my personal amusement and creative relief, by using non-destructive methods. This one really struck many chords with me, especially with TM51's additional info on the KT/Milwaukee D2 and vintage film, some of the other comments, and the further I got into the depths of it during cleanup really made it worthwhile for me, in time and as a tool & shop-aholic.

I won't go into all the details but hopefully the clean up and the pictures tell some more of the story for others. There are 13 pics from the primary: One Cleaned up and another with a Number Key, and the rest are the numbers cropped from the original. There we a lot of machines I couldn't identify and cropped them out as individual pics. I was particularly struck with the Tool Room Guy & Gal in No. 11 & 12 and led me to gestimate the size of the shop based on the bench sizes and the typical head size of ~6" diameter, which puts the shop at ~44' x 40' with a wad of machines and people operating them in ~1800sq.ft. and no overhead wiring nor air lines or coolant supplies...all neat and orderly!

Note: Some of the cropped pics are not as clear because of web resolution and cropping. The original clean up to 24 bit grayscale was 91mb.

First two: clean up and Number Key:

11 in Numerical order:

It's the stories we garner and share, starting with Jon finding these fabulous pics to TM51's D2 story and everyone seeing the Gerstner's and what we draw from our imaginations from the people in them and our past's that bring meaning and substance to what we do, have done, or going to do for ourselves and others.

Thank You Jon!

Last edited by PJs; Jan 15, 2019 at 02:51 PM. Reason: Ooops had 2 7's

‘‘Always do right. This will gratify some people and astonish the rest.’’

Mark Twain

baja (Jan 20, 2019), Jon (Jan 20, 2019), KustomsbyKent (Jan 14, 2019), NortonDommi (Jan 18, 2019), ranald (Jan 15, 2019), Seedtick (Jan 14, 2019), Toolmaker51 (Jan 14, 2019), volodar (Jan 14, 2019)

esp for PJs; and others viewing the video about the mill. That first day, walking into that shop, interviewed and hired, then led to the milling department. A pair of D2 sat front row center. A big Norwegian man was deeply engaged running one, so I was already watching, Uhh-oh-ing silently.

The supervisor; "You're gonna run this one"

Me "I've never even seen one of these"!

Super "That's OK, nobody has. We're going to teach you"

Me, relieved and heaving a low "Whew"

By lunchtime, I was hooked.

With that scene in mind, this is what I still see, watching the Norwegian, even 43 years later. Of 45 seconds, those spanning :13 to :22 most of all.

Sincerely,

Toolmaker51

...we'll learn more by wandering than searching...

Fullsize image: https://diqn32j8nouaz.cloudfront.net...w_fullsize.jpgN. Freeze steam threshing outfit near Sumner, Dawson County, Nebraska. 1903.

New plans added on 01/17/2025: Click here for 2,706 plans for homemade tools.

Tm51 saw some of the video on the d2,,, wow looking forward to watching all of it. That is some mill. The sv4 steinel came it to my bosses business yesterday and I got a look at it to day. Got me a learnin curve head of me! Too many things that are not as intuitive as I would have expected. The table feed gear change looks to be a real puzzle, top lever seems to be pined with no obvious way to change setting, bit like a horse shoe puzzle. There may be an answer under the paint slobber. This is one source of frustration I am looking forward to. Thanks for the posts.

Eric

Toolmaker51 (Jan 18, 2019)

I'm guessing you are speaking of post #416 the dredge.

Modern dredges may have a crew of only 4 or 5 and maybe 10 to 12 persons for some of the larger ones a smaller dredge may have only 2 or 3 workers. since the newer dredges have so many functions that can be controlled by 1 person at a console another to keep it running and maybe one more helper. on the smaller dredges

these ancient dredges most likely steam powered needed several in the boiler room alone plus every function of the machine was mechanical someone or severaal someone's were required at each of the functions.

If you ever saw a Gerstner box you would know it they were like the creme la creme of the machinist tool boxes Made of wood expertly crafted

Still made today although I suspect done by modern CNC equipment

and not all that expensive compared to their cost 50 years ago

https://www.amazon.com/Gerstner-Inte...SIN=B076H7WGWG

Last edited by Frank S; Jan 17, 2019 at 10:17 PM.

Never try to tell me it can't be done

When I have to paint I use KBS products

Coaling a battleship.

Fullsize image: https://diqn32j8nouaz.cloudfront.net...w_fullsize.jpg

New plans added on 01/17/2025: Click here for 2,706 plans for homemade tools.

There are currently 21 users browsing this thread. (0 members and 21 guests)

Bookmarks