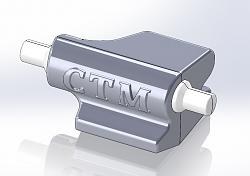

Collaborated with SuperDave to make 3D-Printed patterns to create Metal Castings for a Small Workshop Vice ... and some other items.

I will update this Post after have finished machining the castings ... Aluminum, Brass, and Cast Iron

For the long Story & Lots of Photos Click this Website Link:

https://ctmprojectsblog.wordpress.co...nted-patterns/

The Short story is 3D-Printers are basically toys right now, but there are some things you can do with them like making patterns for Sand Mold Metal Casting.

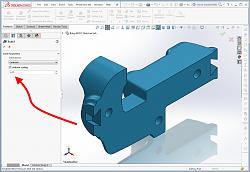

Created the designs with SolidWorks CAD software ... then Split the patterns ... and added alignment holes ... and then converted the files to .STL ... and then 3D-Printed the patterns.

SuperDave cast some of my part designs and some of his part designs.

It might take me a while to machine all these castings, but I am looking forward to the practice.

We draw the pattern designs in SolidWorks and then 'Centroid' Scale-Up the patterns to account for cooling 'shrink' of whatever metal going to cast them out of which works very well to create accurate dimension final castings.

Experimented using carbon rods for cores (Including Air Carbon Arc Gouging Rods)

SuperDave's Idea!!

Short 2 minute video showing the SolidWorks Assembly Design ...

CHEERS!!

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks