Hi, here is my new vacuum clamping system,

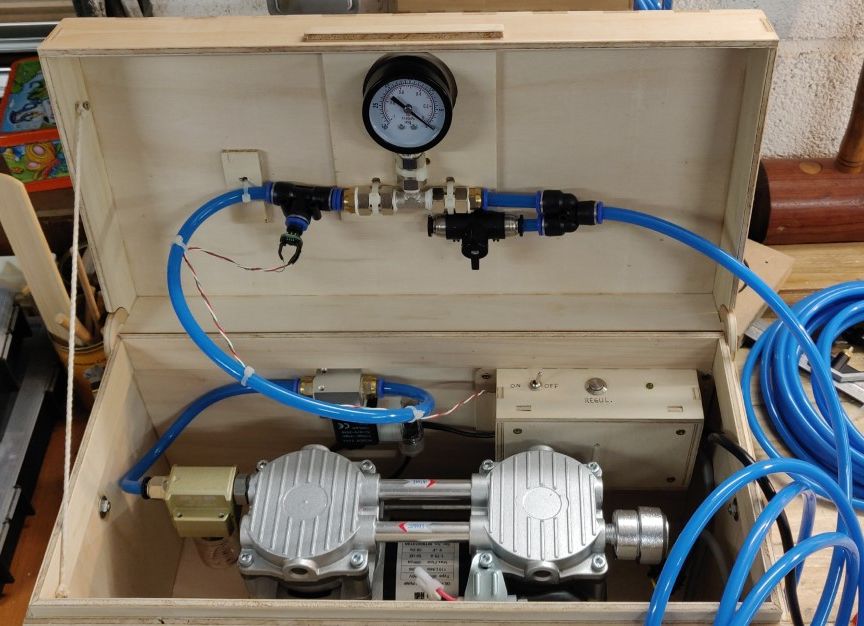

I designed an electronic vacuum control, arduino based, in order to maintain the vacuum level, I integrated all the parts in a wooden transport box, together with the pump itself.

I explained everything in this article on my website, all the details are there, including the code, and an example of application.

I also explain how to make the vacuum bag and the connector for the bag.

Please check it out.

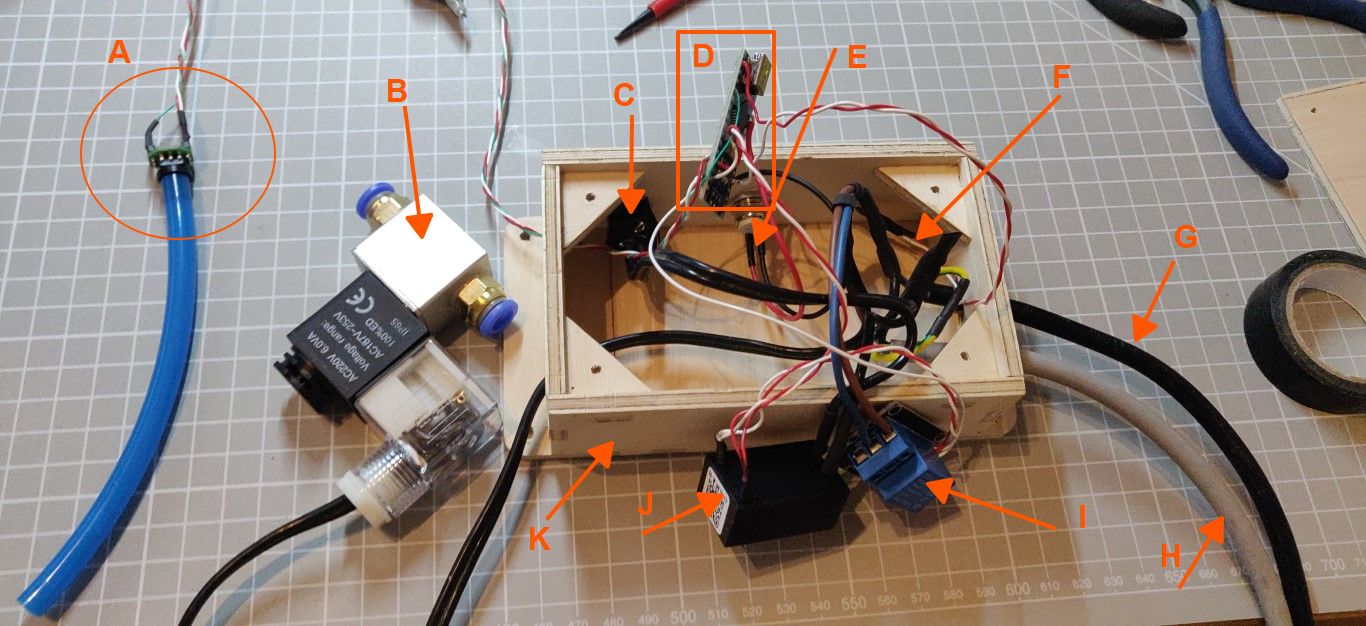

Here are the main parts :

The Box setup

The pump I am using:

The control system:

A - Negative pressure sensor -100Kpa < 0Kpa: 0.5V - 4.5V, model XGZP6847A100KPGN

B - Pneumatic solenoid valve - 220V solenoid - normally closed

C - Main ON/OFF switch

D - Arduino Nano Board

E - push button: regulation start/stop.

F - Led: regulation activated

G - 220V power supply

H - Pump power supply - 220V

I - Relay module: controls the pump and the solenoid valve in parallel.

J - Converter 220V AC - 5V DC

K - “Electronics” box generated with Boxes.py, see below

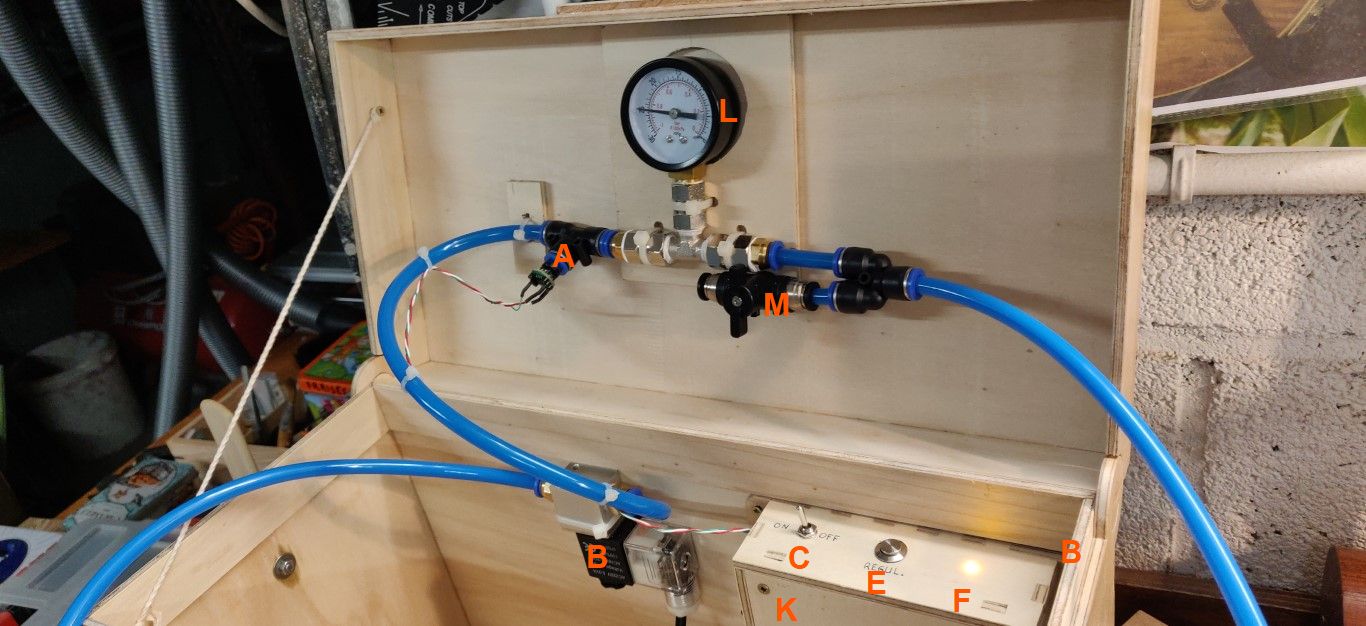

L - Negative pressure gauge -1 bar (-100Kpa) < 0 bar

M - Relief valve, allows the circuit to be brought back to atmospheric pressure

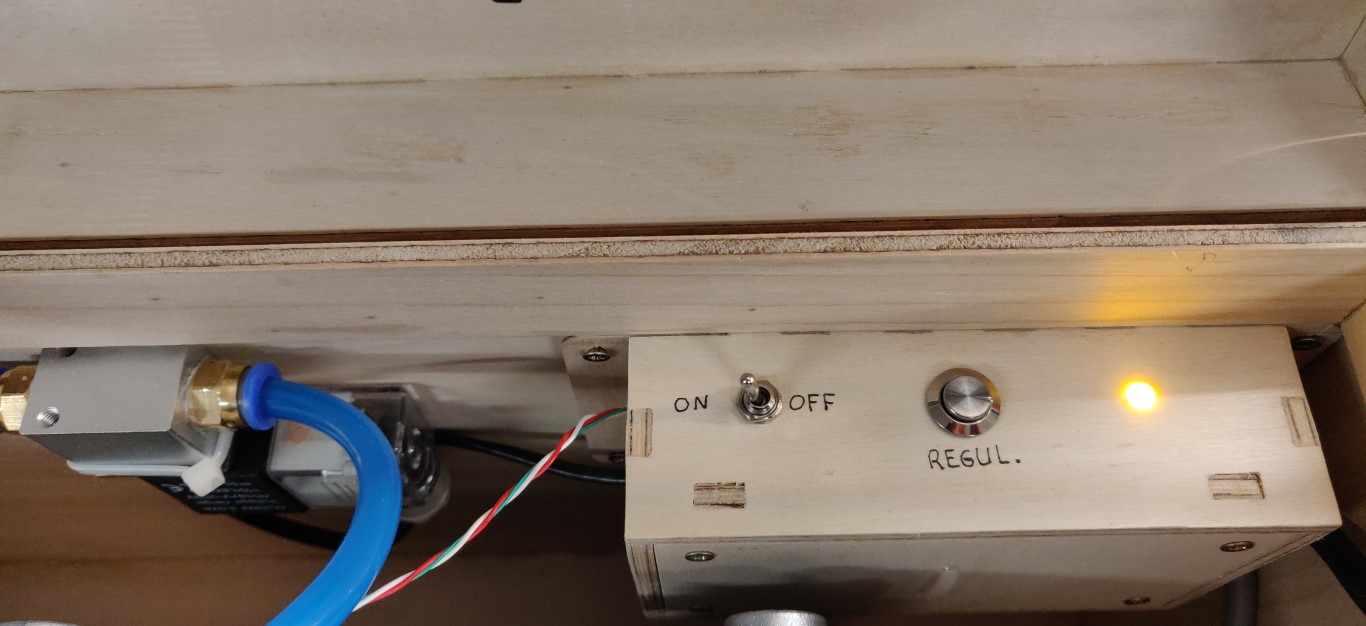

The controls, integrated in a small box in the box :

When the switch is turned ON, the pump runs continuously. When the REGUL button is pressed, the pupmp stops, the solenoid valve is closed and the vacuum is maintained. If ever there are small leaks and the pressure climbs up, the pump reactivates and restores the wanted level of vacuum.

Some views of my nice (yes I like it) poplar transport case:

It's an integrated hinge all wooden case. It's quite unusual and works very well.

The homemade connector to the bag:

The thing in action:

For more details, please see the article (link given above)

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks