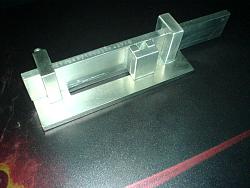

Good idea for spacing the letters. Getting uniform indents is a challenge. Uniform hammer blows is one thing but another aspect is that different letters require different blows. For example the letter "I" requires less force than the letter "M". Most of my stamping is in steel which requires a heavy strike. I use a heavy hammer to assure a good imprint with one strike. I hold the letter stamp in a pair of vise grips which prevents having the stamp fly off to a well hidden place in the event of an uneven strike. I've been thinking about a simple jig that would hold the stamps perfectly perpendicular to the work and also some spacers that would help get uniform spacing. After stamping one letter, replace the stamp with a short spacer of the same dimensions so that the next letter can be placed against it. Any ideas?

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

I did a serious search trying to find the total line length of each character but no joy. There is probably something in the art community, or those that design fonts for a living, but I found zero on the subject. A CAD system could do a much better job.

I did a serious search trying to find the total line length of each character but no joy. There is probably something in the art community, or those that design fonts for a living, but I found zero on the subject. A CAD system could do a much better job.

Bookmarks