Hi All

Finally completed the coolant system on my 4x6 bandsaw.

The system was in need of a filter to protect the pump from the swarf created by the saw.Many years ago I made some filters for a job and had a few spares left over. So off to the “one day I might use it,draw.” and there was two basket type filters.

The only issue was as a basket filter they would quickly fill with swarf and would need constant cleaning. To over come this I decided to use the filter upside down this not only would prevent constant cleaning but a good visual view of the filter, so when a build up of swarf forms around the filter it could be easily cleared away with a brush and dustpan.

The filter can also be removed from the housing if extra cleaning is required or if a replacement filter is needed due to wear and tear.

The photos below show the filter housing, tray and filter in place.

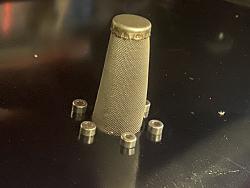

Drip tray and filter components.

Underside of drip tray.

Top side of drip tray.

Complete housing and filter assembly.

Drip tray with housing fitted.

Thank you for viewing

The Home Engineer

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks