I've had a Harbor Freight bead roller for quite a while. It has been a workhorse in my shop for panel fab and now I think it is time to give it some love.

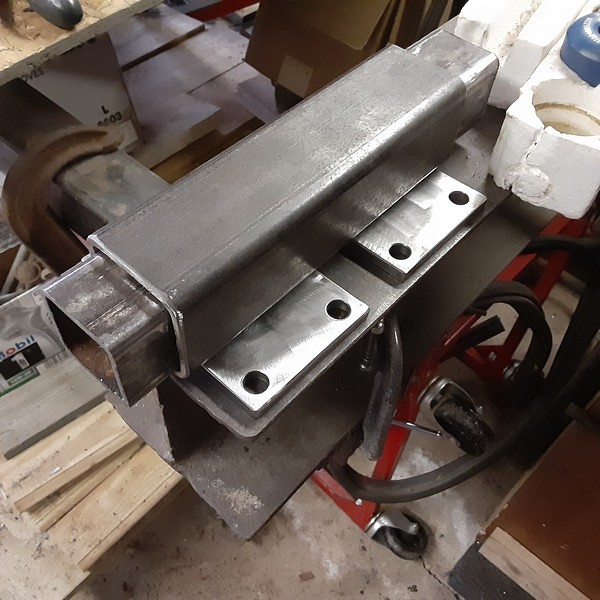

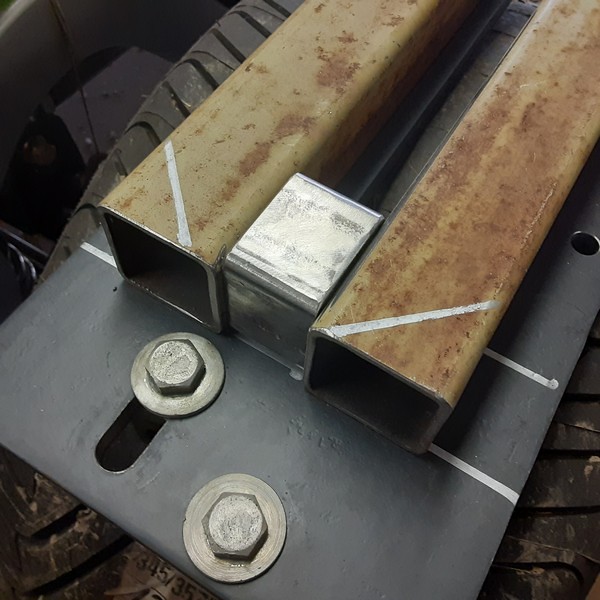

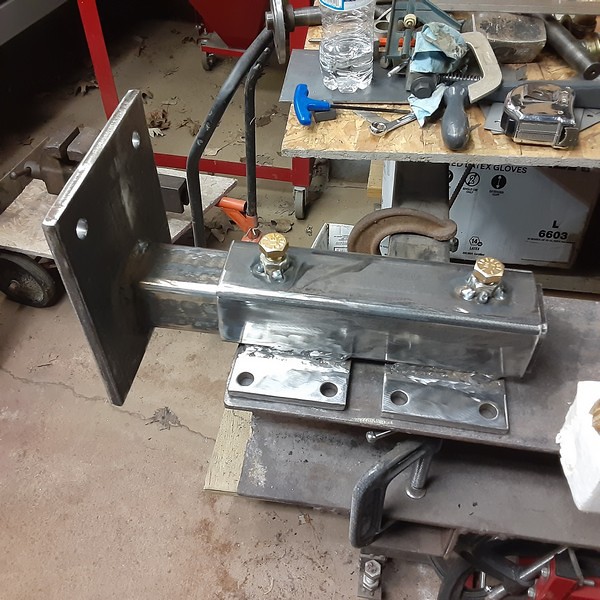

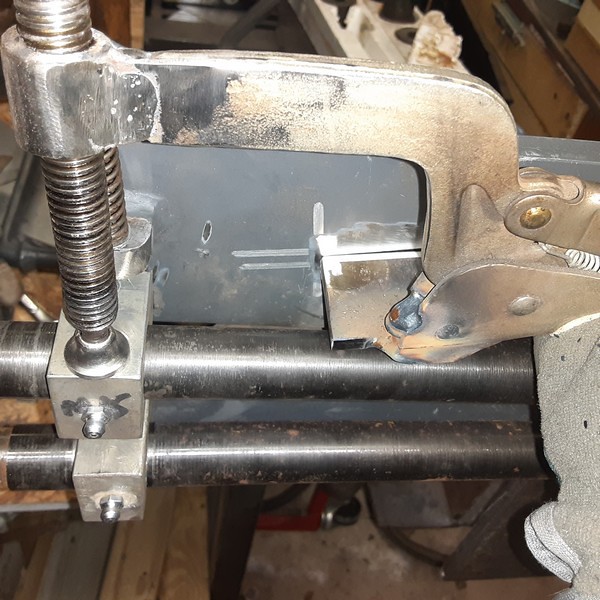

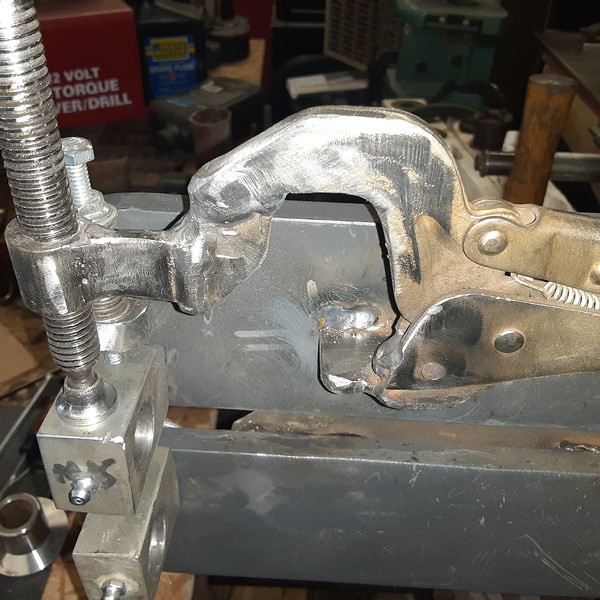

I am doing the tubing reinforcement to the base plate, adding a return spring for the upper die and reworking a Vise-Grip clamp to replace the tightening screw. I am also building a receiver tube so it can be plugged into my chassis jig or the tool stand.

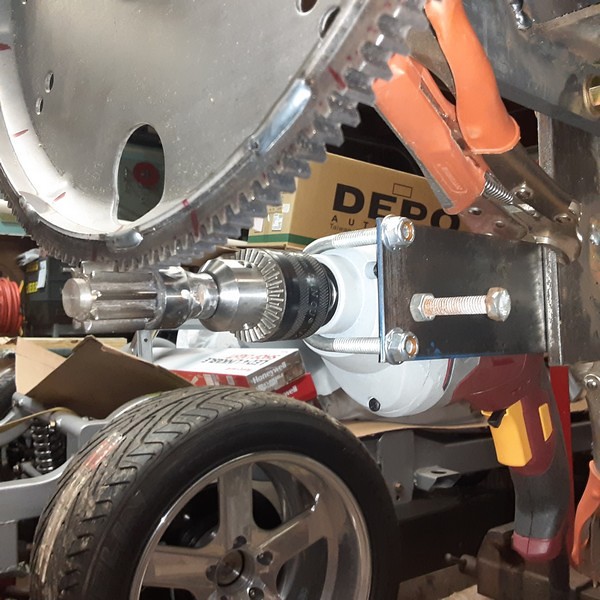

I will also be adding a HF 1/2" drive drill motor to drive it thru an automotive flexplate and pinion gear. I have had a pretty good time getting this off the ground this week. Still have a bit to do but I got most of the welding done today to get the roller mounted so I can put it back together to work out the drill driver mounting.

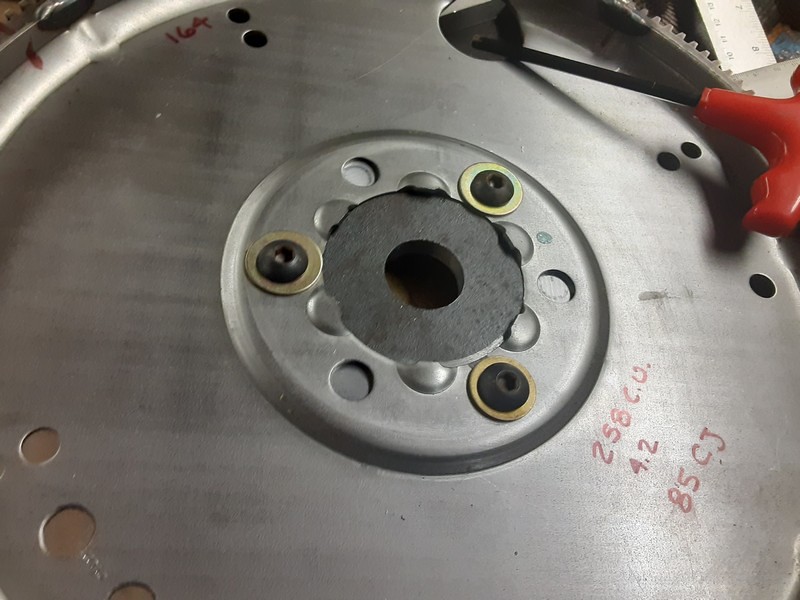

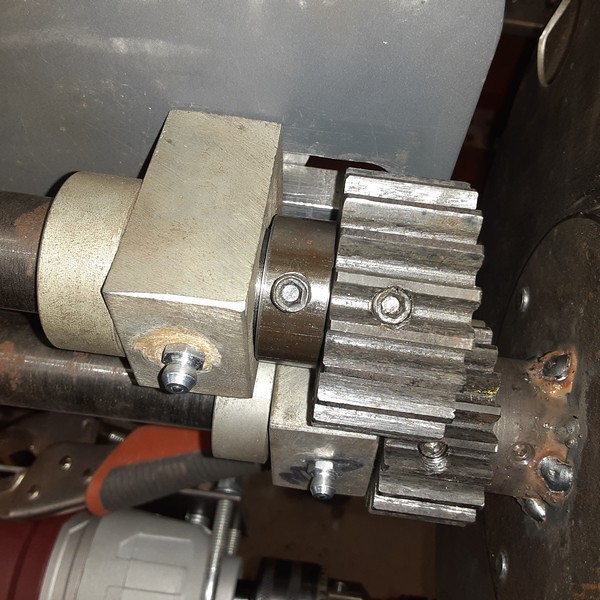

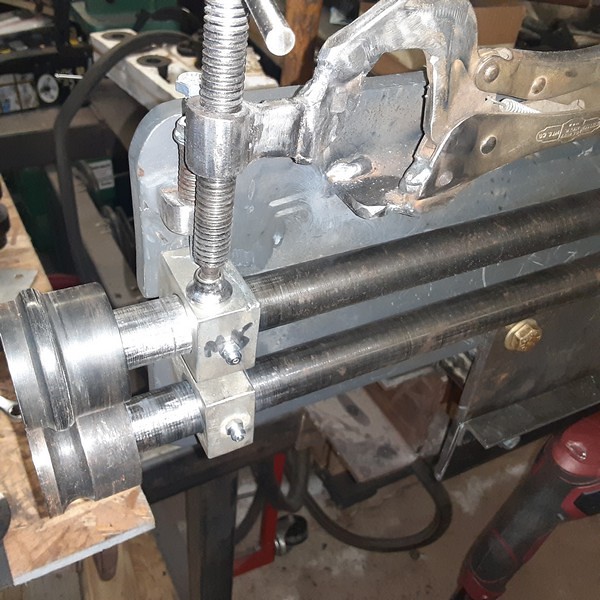

These first few pics are of the adapters I had to make for the flexplate and pinion gear.

Starting the pinion gear adapter. You can see the ID's of the gear in this pic. I am turning the smaller one here. I will turn a shoulder to pilot down into the bigger ID then turn the adapter around in the chuck to spin it down to about a 1/2" to fit the drill chuck.

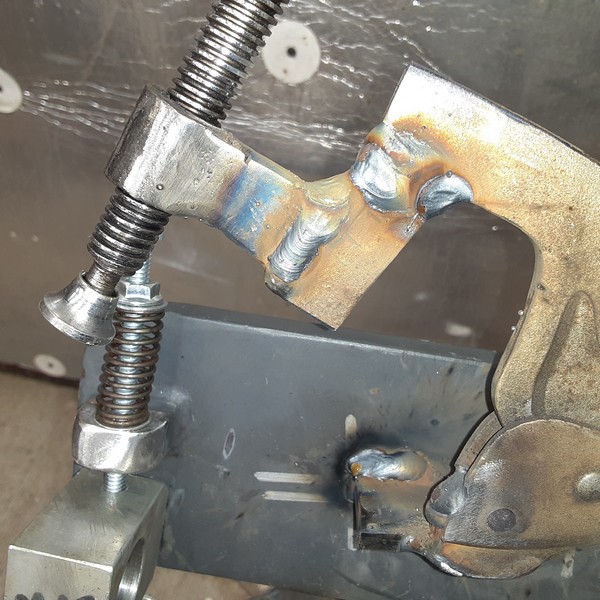

I made the flexplate adapter out of a piece of 3/8"s inch plate and a keyed bushing. The bushing will have to be bored out to fit the roller shaft and then welded to a plate. That I chunked out with the bandsaw and a cutoff disc then mounted it in the mill and cut the center hole with an 1 1/4" Rota-Broach. perfectly round hole and it fit the step on the bushing like a glove.

That hole was then used to bolt on a mandrel so I could chuck the plate up into the Lathe.

I faced the plate about a 1/16th on an inch and brought that diameter down to a snug fit in the pilot hole in the flexplate.

This locates the flexplate nicely so it should run fairly true to the shaft after it all put together. After drilling and tapping a few holes gets this bolted up.

I'll add more pics later, it's getting late and I am ready for bed...

Mark

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks