Hi all,

Previously i have posted information regarding the upgrade of my miller to CNC, about using GRBL as a controller and my Plasma table build.

Im now starting to get quit involved in converting and assisting others in various conversion projects so thought it was about time i wrote a serious thread.

During Covid i have been busy converting my mill yet again, It has gone down the linuxcnc/pathpilot route, I was starting to realise the limitations of using GRBL as a machine controller. I was looking for canned cycles, conversational programming and a better tool change method. Unfortunately GRBL does not handle these very well, By switching i have also gained a 4th axis. I have not got to make chips yet but as far as i hve read this is true 4 axis and not 3+1. Happy days.

Over the last 140 odd days (of the end of the world) I have helped a guy convert and old Denford mill to a linuxcnc styled machine and dumped a whole load of design information on another chap building a plasma table and torch height controller. There are also plans afoot to design and build a wire EDM machine.

The miller has gone through a number of development changes but is now starting to take on a life of its own, shortly before lockdown i was making parts and had managed to get the accuracy and repeatability nailed. The major issue was the worm screws, one of the conversions involved ripping them out and replacing them for precision ball screws. I went from 0.7mm of backlash (yep you read right) to 0.05mm of backlash. To be honest i hadnt even tried getting that improved on before i started to get peeved with GRBL. I am now in the unfortunate position of being a Pathpilot shadow user. If i had the choice i would buy a Tormach but unfortunately the UK market is one they are not very interested in. So clone it is.

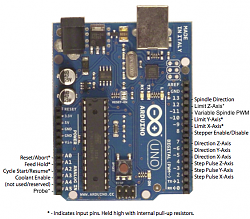

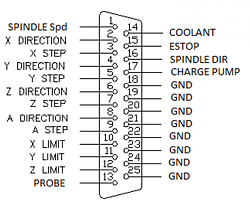

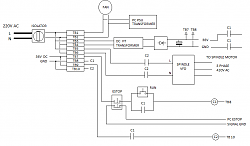

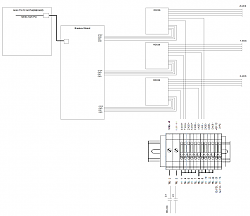

Having purchased the software for the token admin charge, I went about upgrading my machine, I purchased 2x Mesa anything I/O interface cards, the type used in Tormachs machines then started the build. The first stage was to build a new controll panel. the old GRBL electronics had served me well but sadly were very limited and had injested so much grinding dust looked 50 years older than they were. wiring had turned into a snakes wedding after various ripup retries and repairs so i was focused on a new panel anyways.

The reasoning behind the 2 mesa interface cards was the i had an older version of Pathpilot which used a PCI interface card and i was intending to build the machine to match the new upgraded Pathpilot version which runs on its own network connection. The panel was constructed offline/off the machine so that the machine could be left operational until the last minuet. I etched and built a breakout board/pcb so that i could make wiring connections to the Mesa interface card and then made the appropriate wiring connections within the panel.

The build was really simple and straight forward, the advantage was that the machine was already wired with limit switches and stepper motors so the dirty stuff on the whole was already done.

The idology behind conversion to CNC and the alternative the retention of manual milling comes down to on simple question. do you love standing infront of a mill and get excited by the wonders of producing a single part every now and then, or is your ambition to have the ability to make parts. The debate for manual milling over CNC will go on for years. For me its about making a part to suit a requirement, yes i enjoy watch a tool all day ripping steel and making things shiney but the back ache and length of time it takes is non productive. Also im not retired.

The machines appearance has not changed much

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

) kind of pointed me to go over to Tormach and look at PathPilot. I didn’t specifically see them selling software as a separate product. However, they sell a controller with PP ver.2 installed. So I was wondering; did you buy just PP software or did it come as part of some other purchase option?

) kind of pointed me to go over to Tormach and look at PathPilot. I didn’t specifically see them selling software as a separate product. However, they sell a controller with PP ver.2 installed. So I was wondering; did you buy just PP software or did it come as part of some other purchase option?

Bookmarks