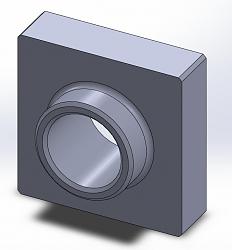

So, I do have some machining experience so I thought they first order of buisiness is to make some T nuts once the milling part of my Unimat shows up. I have not decided if I am going to make them in billet AL or out of steel. The machine is rather small so there is not a whole lot of pressure on the the T nuts. I may have them type 1 hard ano'd if I do them in aluminum. Out of steel, do I really need them heat treated? Probably not and would probably just send them out for black oxiding to control rust. The through hole will actually be tapped 6mm x 1.0. I just chose not to model the threads but they are on the print at least. I'll know for certain how they work out once I make the first batch of them before putting up the print however. And just in case anyone asks, (because many do lol) I used Solidworks to model the part.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks