Originally Posted by

JoeVanGeaux

I enjoyed the account of your Unimat 3. I have the very same model that I inherited from my dad. I recall the day we both "bit the bullet" and went to downtown New Orleans to get some equipment to finally get busy making things. This was back in about 1976.

We each spent over a month's pay on tools. He bought just about everything he could afford to make the Unimat 3 a usable addition and I bought nearly every other tool (in its miniaturized version, of course) which included a Dremel drill press, scroll saw, table saw, drill, vise and many other tools and accessories - tools that I STILL use to this day - though I save those tools for projects more suited to their limitations.

I have always bit my tongue when people trash these tools! If you have nothing but a hammer, dull hand saw and a small set of screwdrivers, wrenches, re-claimed screws, nuts and maybe a box full of re-straightened nails (No sockets, mind you!) then you scored well beyond belief with these tools. With these you can do things, otherwise, not practical or at least very awkward. For example, I actually cut a top for a workbench inside my apartment at the time from a full sheet of 3/8" plywood - one long 8' cut and another 4' cut on that tiny Dremel table saw!! I could only see the blade, my marked line and the surrounding floor during that cut while slowly feeding the sheet.

I have only recently thought of selling that machine to get tools I need now, but I always stop short after recalling the memories associated with those tools!

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

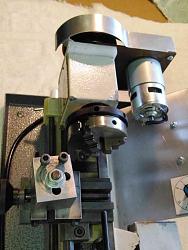

Shop still isn't quite together, but it's close enough I can almost taste it! The more tools you have, the more options you have. If you're going to get rid of tools, make sure you replace them with tools that enhance your capabilities. I traded my 7x mini-lathe for the Unimats. I lost a little bit of capability, but gained much more. And I still have the Heavy 10L...

Shop still isn't quite together, but it's close enough I can almost taste it! The more tools you have, the more options you have. If you're going to get rid of tools, make sure you replace them with tools that enhance your capabilities. I traded my 7x mini-lathe for the Unimats. I lost a little bit of capability, but gained much more. And I still have the Heavy 10L...

Bookmarks