Here is the latest project for the shop. I have a good single bit fly cutter with an r8 shank that works great

in my mini mill. It was built using Rossbotics plans:http://www.homemadetools.net/forum/f...585#post124734

I wanted to make one a bit larger and with two bits to see if it would provide an even smoother cut.

Well this is the result and it provides a glass smooth finish, at least by touch. You can still see tool marks but you

can not feel them. This may be my best fly cutter for a smooth finish.

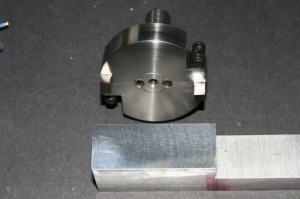

It is 2.5" in diameter with a 5/8" shank. The shank is drill rod and the fit is interference by about .002".

I wanted to make sure it would not turn on the shank so I added two set screw cotters. The cotters

are 1/4-20 and secured with blue loctite. As Tom Lipton says, "nothing built too strong ever broke".

https://www.youtube.com/channel/UCZC...yjrKT4OZne-JNw

The cutter disc was placed on the shank prior to final finishing on the lathe. Lathe bits are 1/4" and are a slip fit in the grooves.

10-32 allen cap screws secure the bits. The cutter disc is .750" thick and made from a chunk of hot rolled steel. Having a square 5C collet block really helped to get all of the milling and drilling lined up.

I think it should out last me!

Cheers, JR

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks