This is more of a mechanics hack than anything else.

A lot of times I find myself having to assemble parts with multiple bolts in awkward positions.

This is particularly true when replacing the air operated fan clutch on a Mack engine and doubly so when you do not remove the radiator.

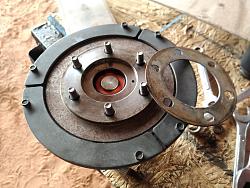

The Borg Warner Air operated fan clutch has 6 recessed bolts that holds in on there is also a spacer shim between it and the water pump pulley making it all the more difficult to hold everything and start the bolts which also have split lock washers on them as well.

It is all too easy to drop a bolt inside of the housing assembly or loose a lock washer off while trying to insert the bolt.

loosing a washer or dropping a bolt inside especially after having successfully instilling the previous 5, only leaves you with a single course of action,

Remove it vigorously shake the housing until you can get the bolt or washer in position to remove it with a slender probe magnet or needle nose pliers. You may get lucky though and it falls out.

Here is a little trick I learned when dealing with an assembly and a handful of bolts to capture them in place.

Sometimes a spot of grease will suffice but there are times when grease contamination is unacceptable.

Other times a single rubber band stretched around all of the bolt shanks or a string tied tightly around them will work if you can cut loose the anchorage after the bolts are started.

Another way is to use O-rings, as I did in this case. I placed a bolt in position then rolled a small O-ring over it to hold it in place.

As with the fan clutch many things have a small camphor on the holes allowing the O-ring to be left in place

This allows me to hold the assembly slightly away from the mating part and one by one start each bolt a few threads

If you just jam in in place you will risk knocking most if not all of the bolts out of their holes.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

$&^#(@*

$&^#(@*

Bookmarks