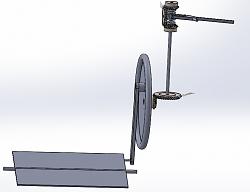

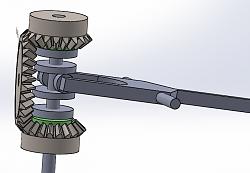

Purchased a hand-drive leather sewing machine because I don't have strength in hands to hand-sew leather. I want to look into making a treadle drive for it when it comes and don't see a lot of information on web on theory, construction. I do have a treadle operating Singer machine for fabric but looking at the design of drive I will need something stronger to pierce the leather; a weighted flywheel to provide the power to pierce leather; a drive that would enable single stitch advancement; a means to 'hand-advance' stitch on edges/ends/back-stitch.

Just rolling some ideas around in my mind. One is the use of a 90 Volt DC motor and speed control but the kind of power it delivers I am concerned that would brake something rather then just jam it thread should bunch up.

Thought that there is nothing like kicking an idea around to help develop a solution.

Gord

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks