I have never had a travelling steady for my SB lathe and have managed so far without, however I needed to make a longer Acme crosslide feedscrew and the orginal had by now some .033 thou backlash so the time had come to first make a steady.

I have never understood why most lathes have a steady cantilevered over the crosslide mounted on the tailstock side, I tried to fabricate a copy of this but it was not rigid enough.

I decided to make one from ½ inch ms plate and mount it on the chuck side which is pretty much where the tooling is.

The next problem was an unmachined surface on the saddle to bolt it to so a flat surface was created by using the topslide as a ram mounted vertically on a bracket to plane the surface, I use the topslide for cutting keyways so I already had a lever linkage available.

This went very well as cast iron is easy to machine and hole positions were marked out with the same tool to match the originals on the other side of the saddle so it can be used on both sides.

So its off with the saddle and drill and tap for two 8mm bolts and a good chance to give it a clean before replacing.

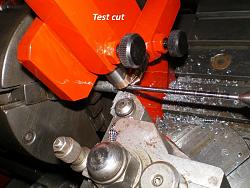

After mounting the prepared and drilled plate a 1.75 inch hole is bored in position and the surplus cut away, the bronze tipped fingers are fitted to square blocks brazed in place with locking finger screws and in this form has proved to be very rigid in use and has enabled me to produce a good 9 inch long feedscrew and two taps to match. With a new bronze nut, backlash is now only .005”, something I can mentally allow for instead of putting pen to paper when indexing.

By the way I don't have a red paint fetish its just that I have a large qty of red enamel so its use it or lose it.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks