Making the steering wheel adapter for the van I had to swing the mill head to 32 degrees (as far as the FrankenMill would go) I needed 40 but the head wouldn't clear the body of the horizontal mill. I hate having to tram the mill but it had been a while since I had done this so knocking it out of alignment was a "good" way to recheck things.

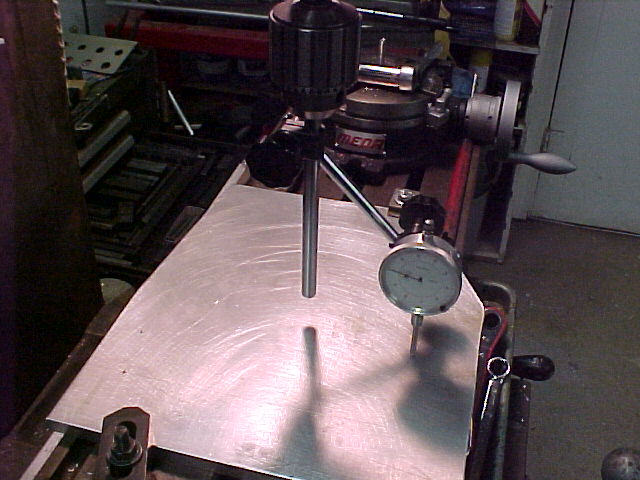

I have a piece of flat 1/2" aluminum tooling plate I use for the purpose. I clamp it to the table and set the dial indicator up.

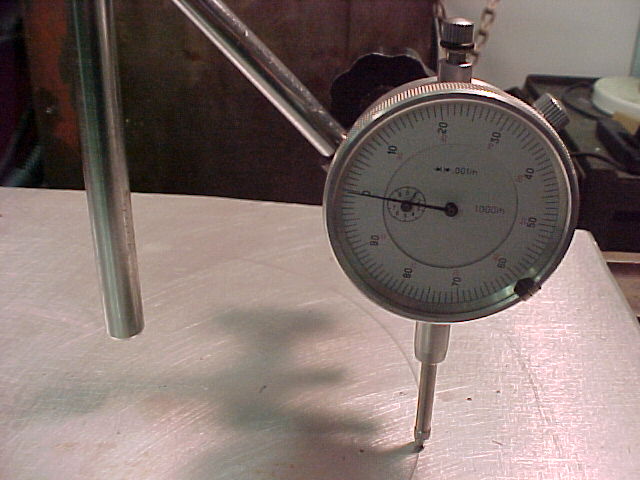

I just take it apart and clamp the main post into the chuck.

Now I can zero the indicator and swing it to the back side of the plate to see what the damages are.

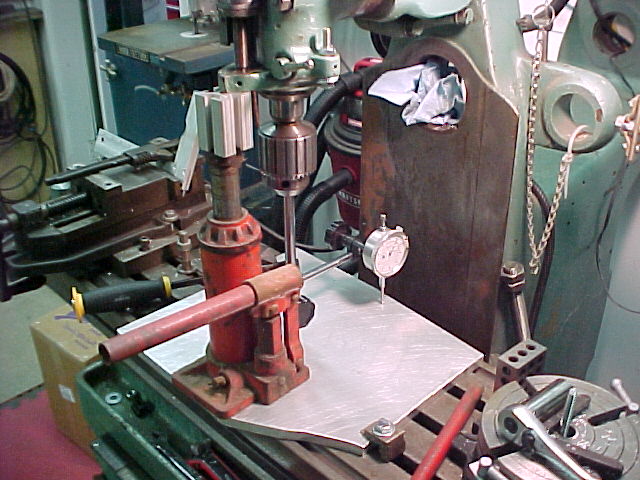

The first step is checking the nod. This was out by about .030 after swinging the head around so I set that first. I use a bottle jack to support the head as I loosen the bolts. The jack makes it really easy to adjust the head up and down.

After a couple of swinging sessions I got the nod to less then .001 which is fine for the work I do on this machine. The tram I got to nearly 0.0, well under what the dial indicator will read.

This makes for a pretty cheap tramming set-up. I think I paid 30 bucks for the dial indicator set many years ago.

Mark

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks