I made this little tool holder to replace the cumbersome one that came with my 9” X 20” Harbor Freight Lathe I bought about 10 years ago, I use to add shims under the tool bits to get them to the right height and that was a pain in the butt so I put a shim under the tool post and that worked for years, but I wanted to make something that was a little more user friendly seeing that I wasn’t going to buy a quick change nor was I going to make one for this chineeze machine, I don’t use this machine much but it does come in handy once in a while.

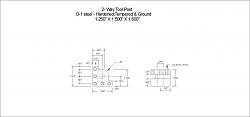

This holder only has two places for tools; it will be setup mainly with turning and facing tools but they can be changed quick enough, the holder can be rotated at any angle and locked down using the existing locking lever that came from the 4-way tool post, I made the tool holder so it would accept 5/16”sq tool bits and that the top of the bit would always be on center of the machines axis, no more shimming, the reason it only accepts two tools is for side relief when using the live center, this allows me to work close to the center with very little tool overhang, plus it is incredibly smaller than the 4-way and allot less bulky.

Measuring from the top of the cross slide to the top of a ½”dowel pin mounted in the lathe chuck then measuring to the top of the compound and with a little kindergarten mathematics I came up with the measurements to make this tool holder.

The holder was made from O-1 steel, hardened, tempered and ground, it came out as planned and functions as intended.

This is only one of the multitudes of things I have done to this lathe and I’m sure in the future there will be multitudes of others.

Below you will find some photos of the machining processes and the finished tool, I also included a drawing.

As always, thanks for looking and happy machining

Doug

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks