After using a Tiplap tool sharpener for many years I really missed this excellent machine when I retired, particularly when an accurate screw cutting or acme tool bit was needed.

Buying one was to expensive for my now occasional use but making something similar out of the scrap box seemed feasible.

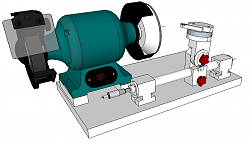

I already had a spare six inch bench grinder and a steel baseplate to mount it all on (I am sure a decent wood base would be ok).

A cupped diamond wheel is used and I was fortunate in finding a damaged on for a song, a one inch chunk had been knocked of the rim and this was repaired with plastic metal and has been used for many years now.

The only accuracy needed is the squareness of the bar in relation to the wheel, this is easily achieved by placing a flat bar or disc on the wheel and using a DTI in the tool holder until squareness is obtained at which point the end blocks are bolted down.

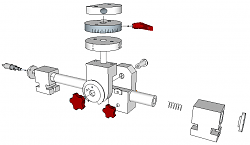

Sizes are flexible to suit your needs , mine uses a 1 inch bar an easy fit in the alloy blocks.

In use I rarely clamp the tool being ground as thumb pressure alone seems to work combined with the end stop, It also makes it easy to remove the tool for inspection and replace it exactly where it was for further grinding. It works very well in sharpening carbide tools and tips.

This is of course a finishing process keeping the land to about .050 max after the blank is roughed out using a grit wheel.

I have also sharpened end mills and twist drills (4 facet method) with a few simple fixtures.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks