My dust extractor is OK for the larger tools (planer, radial arm saw etc) but my shop vacuum is more mobile and therefore more suited for use with smaller power tools (sanders etc). To reduce filter cleaning and for ease of disposal of sawdust, I built a Thien Separator.

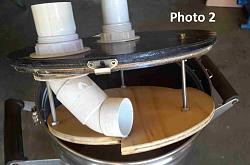

As we live at the coast, I try to avoid rust-prone materials. A 25 liter plastic bucket proved unsuitable as the suction from the shop vacuum deforms the bucket. I then repurposed a 30 liter stainless steel hot water urn to serve as a separator (Photo 1). Standard 40 mm plumbing fittings were used for the connections (Photo 2). The intake uses 2 x 45 degree elbows, rather than a 90 degree elbow, to provide a smoother air flow (Photo 2). The slot in the baffle is 20 mm wide and the rest of the design is as per Phil’s design.

Castor wheels were affixed outboard of the urn base, to provide better stability (the separator gets dragged around the workshop by the pipes) (Photo 3). Thank you to Phil Thien for the design, it works a treat. NO sawdust ends up in the shop vacuum and hardly any dust gets to the filter. As the urn is watertight it can also be used for liquids. The tap could be left in place to empty the separator if it is often used for liquids.

(Credit for the design - Phil Thien at J. Phil Thien's Cyclone Separator Lid w/ the Thien Cyclone Separator Baffle).

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks