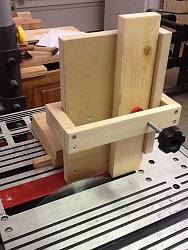

This is a jig that I put together to help me make better mortise and tenon joints. This little fixture has really improved the accuracy of my tenons. I cut out a runner to slide in the T-rail on the saw in the X axis, parallel with the saw blade. A cross slide is fixed to the runner that allows the user to set the position of the workpiece to an accuracy of 1/64" in the Y axis, perpendicular to the blade. The height of the cut, which determines the depth of the tenon, is set by raising and lowering the saw blade. Typically, this is not required to be very precise. But this can be accurately set using vernier calipers to set the height of the blade above the table. The hardest part of this little project turned out to be coming up with satisfactory way to hold the workpiece firmly in the jig. None of the clamps in my shop worked very well. In the end, I made a clamp that would grab the back of the jig with a screw clamp that holds the work against jig.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks