I need some help here.

I have a keyless chuck in my mil part of a combo machine.

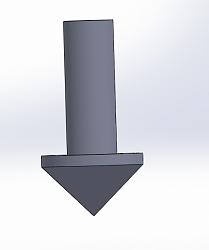

Problem is that when I want to use the chuck to do some tapping...turning the chuck by hand the direction of turning is the same as loosening the bit from the chuck. I am left with the small thin ring at the top to turn the tap.

I did a search here so I would not bore you with an old problem that has many solutions. On my bigger taps I used a sharpened pin to go into the back of the tap and then the normal tap handle to turn the tap, but not all my taps has that little centre hole.

Please

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks