another little widget, the making of which helps keep me sane!

I've long had issues starting dies straight, perhaps because I have crap dies, perhaps because I'm not doing it right, but either way I thought this was a neat project to do. Also, seeing jjr2001's thread on it helped

A chunk of 2in steel rod was hacksawed off and faced both ends, then dialed in on the 4 jaw.

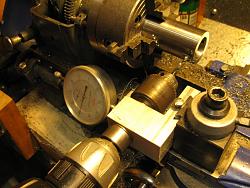

Using my toolpost drill chuck - an absolute necessity on a lathe with 1 1/2in tailstock ram travel - I drilled the rod out to 1/32 or so under 1/2in diameter. Then I reamed it to 0.500 dead on. I thought that was an over reamer, but now I know!

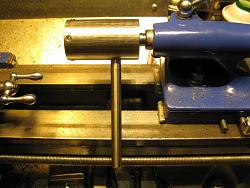

couple of pics showing the 3/8in shank arbors I made, one for a 3/8" chuck, the other for a 1/4" chuck

with the work still in the chuck, I bored the face to accept a 1" die

then cross drilled it at 90deg around the circumference to tap holes for 10-32 set screws

next up is the arbor, using a rusty old 3/4" ex-axle. Faced then center drilled for a dead center. Then turned it down to around 0.501.

then ground it to fit using my Dremel and tool post attachment (first use!). Wasn't perfect, but with a bit of patience and some sand paper got it down to 0.499-0.4995, so a nice tight slidding fit into the die holder.

Parted it off, turned it around and cut the MT1 taper (not shown)

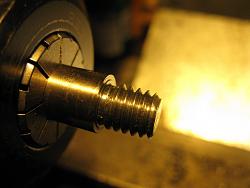

Turned down the handle to the major diameter for 5/16-18 (drilled and tapped a matching hole in the side of the die holder)

and threaded it using my tailstock die holder

all finished

also made sure that the arbor was long enough to pop the die out - my USA made dies are a bit larger than my Chinese ones (which I think are actually 25mm, not 1")

anyway, feels good to get another little project done and another useful tool. Also got to use several different useful tools I made a little while ago

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks