Hello everybody,

This is my first post. I was gladly surprised time ago with a contact from homemadetools.net advising that my homemade table saw was among the 50 Best Built Homemad Tools book!

I am now please to inform you that the saw continued its evolution as described below.

This saw falls in a category which, to my knowledge, has not been catered for to this date. European Format Style saws are very modern machines evolutioned over years of sound development. They show a common trait in the form of a sliding table and considerable safety measures integrated in their design. However, most show two drawbacks: They are too big for a home shop and they are quite expensive.

Since I built my first cabinet saw in 1997, loosely based in Gilliom plans and some parts they supplied, I included a first version of a sliding table. I was never fond of miter slots. Over the years the initial saw endured many modifications, the last one in 2015. It then acquired the looks and operation of a Format saw.

By then I was approached with a fellow woodworker from Germany who wanted to build a replica for his own use. I am quite happy with my saw as it is and being 80 years old will not be building a new version for myself. But I did have a few additional ideas which were begging a try and this new friend provided the enthusiasm and opportunity to do that. To make a long story short, he finally enticed me to draw detailed plans and eventually built my new design impeccably. He also provided invaluable help in checking my drawings and helped in ironing out design details detected during construction.

The enhancements proved to work well and we finally agreed to team up and have our own website where plans are offered for sale and a lot of information supplied. The site received a name: www.aw-thinkbold.com and interested parties can buy a 81 page package which includes 38 pages of text with step by step instructions, 43 pages of dimensioned drawings of all components of the machine and a photos file with 232 pics with comments showing different parts and construction with great detail.

It would be a fallacy to pretend this design to compete with commercial equivalents. However, it replicates all the features within the possibilities of a homemade equivalent. Some things are missing, such as a scoring blade or the possibility of cutting dados. Both involve complicated mechanisms and specialized blades.

But there are several advantages. The design itself was kept simple. Main material used is 18mm plywood, hardwood and some MDF. Metal parts and some lathe work are unavoidable but reduced to the absolute minimum. Commercial items (such as T-track and knobs) are used. However, we are constantly looking for simpler substitutes because not all parts are available worldwide.

Some of its features merit being highlighted:

- A true sliding table running on round steel bars, with a floating carriage, providing a 100cm travel. The sliding unit is fully adjustable on three axis using bolts and nuts to provide a firm and stable platform. Very smooth operation.

- An Outrigger Table coupled with a Telescopic Arm to support large panels during cutting.

- An innovative mechanism to raise/lower the blade vertically by pushing/pulling the motor which is mounted on heavy duty ball bearing slides. This simplified enormously the task of fitting a Riving Knife.

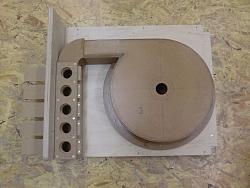

- An integral Dust Collecting System with a Thien Separator and an easy accesible generous sized Dust Bin. There is a Manifold with 5 Blast Gates (two used for the saw) that allow connecting additional tools such as a Router or using the DC for general cleanup.

- A short, reversible, Rip Fence to European standards with micro adjusting. A new mechanism locks the Fence first and then allows adjustment.

- Two Crosscutting Fences. A large one for the Outrigger Table and a short one for the Sliding table front. Both adjustable to + or -45°. Positive, adjustable 0° stops in both cases.

- Integral retractable wheels to move the saw wherever wanted.

- 250mm diameter Blade, tilting to the right. Blade cover with dust pickup from above.

For more information, pics and videos you are welcome to visit the above website.

I hope you like this machine and will be contributing in the future as time permits.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks