Originally Posted by

Sourdough

I make small tables, trays, and such, in my one-man company in Montana. When I see a design that makes me wonder "Could I built that?" I may go for it. I also make chairs and cradles for dolls (though there are no dolls in my shop).

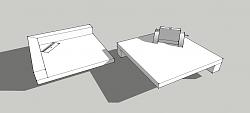

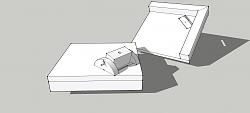

Jigs interest me. Now, I want a jig to hold table legs at an angle for drilling. Most such jigs online tilt back to front but the length of a leg demands a jig that tilts sideways, and tall enough for the leg to clear the edge of the drill table. Suggestions will be appreciated.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks