My brother left me a cheap Home Depot table saw when he moved away. I have been using it a lot recently, but I have been completely frustrated with the absolute garbage fence it came with. It takes forever to get it parallel to the blade, it is not square to the table, and it has a wave down its length. I would love to invest in a quality saw, but do not have the means to do so at this time. Since I have more time then money, I decided to modify what I have.

There are many videos and websites that I found that showed how to make a T-square fence. The fence itself is basically the same as all the others. The problem I ran into was that my saw did not have a removable track or a flat front for mounting the new track. The original track for the fence is molded into the front edge table saw deck. It seems to be a common design on most budget table saws but becomes a problem when you want to mount a new fence system. I came up with a work around that I hope someone else in my position might find helpful.

I happened to get another treadmill donated to me by a friend. It had a good amount of usable steel tube that I was able to process with my homemade band saw. The only other significant pieces I used were angle iron. I started with 2 pieces of angle iron bolted to either side of the saw. There were already holes there for some purpose so that made it easy. From there I welded tubes to the bottom side of the angle to hold the main horizontal tube that would be used as the track. This dropped the track down low enough that the fence would not interfere with the miter tracks.

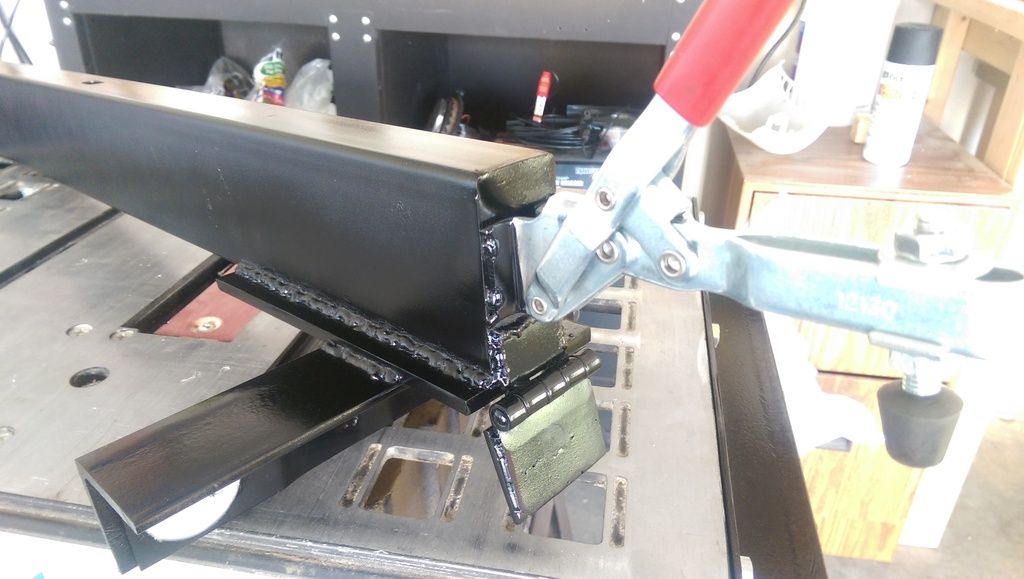

FYI - I am not a very experienced welder so please don't make fun of my welds.

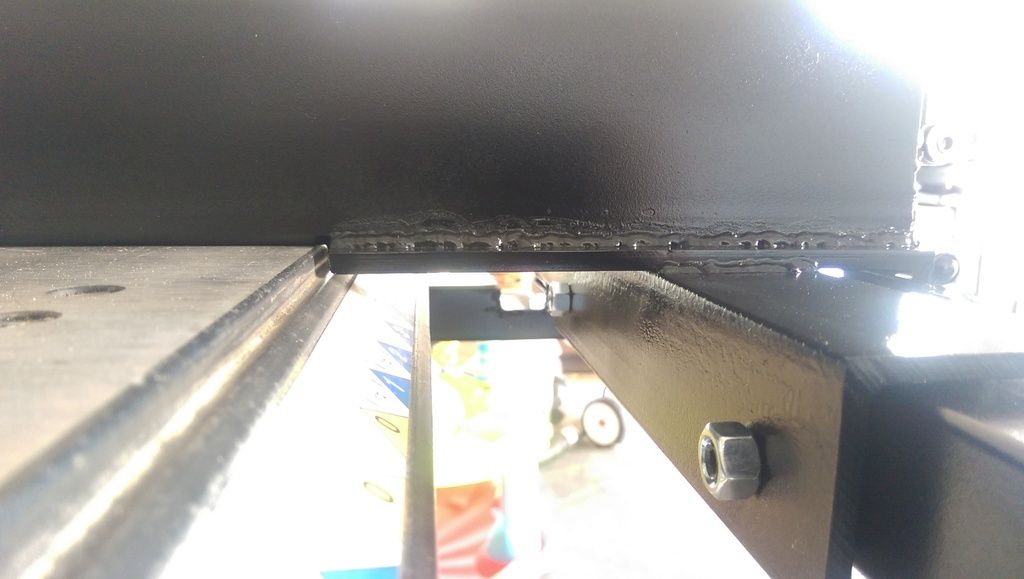

I did end up having to put a C-notch in one of the tubes to allow for the angle iron on the fence to pass over. This could have been avoided by using a smaller piece of angle or trimming one of the legs down. I didn't feel like doing either at the time so I just notched it out and welded in a half section of tube.

Here it is cleaned up and painted.

As I mentioned, the fence itself is just like all the other t-square fences. It has a piece of rectangle tube welded at 90 degree to a piece of angle iron. I threaded set screws into the angle iron for fine adjustment and glued nylon washers to the underside. The hold down mechanism is a $5 toggle clamp from Harbor Freight. The toggle clamp presses against a hinged plate to prevent denting/crimping of the tube used for the track. I did not take any assembly pictures of the fence. I get caught up in what I am doing and forget.

I put several coats of car wax on the track and lightly sanded the washers. The fence glides back and forth surprisingly smooth. The toggle clamp holds the fence securely with little effort. It will even hold it square way out on the right side where there is no table to support it.

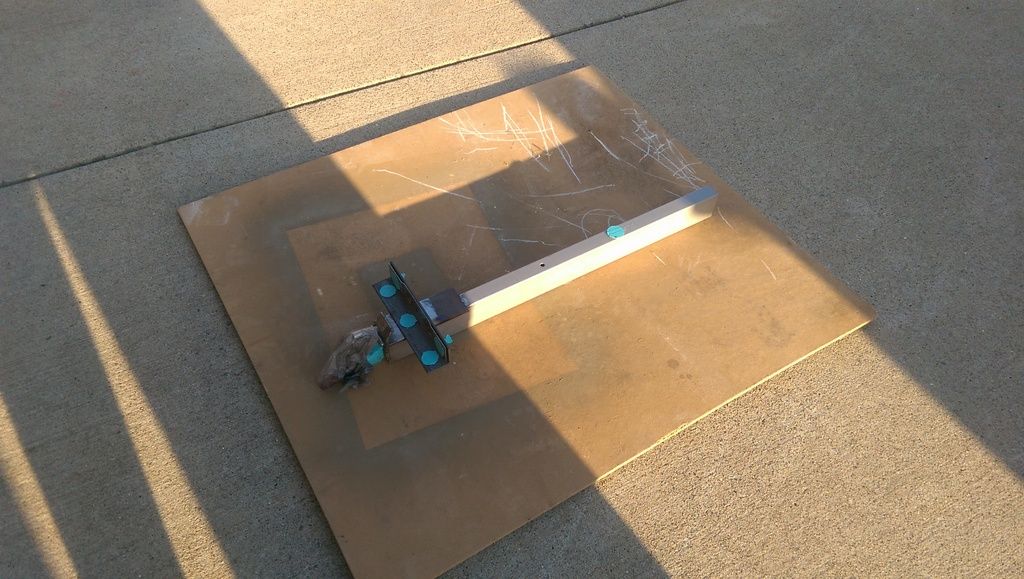

Last night I started making the extension table. I used the wood deck the came from the treadmill. This is the piece that you run on under the treadmill belt. It happens to be 3/4 melamine. I also used a piece of it for the face of the fence.

Since I got the metal for free, I might have $15 in the whole thing. It has been working awesome. I no longer have to measure at both ends of the saw blade (I still do out of habit but it is always the same). Once I get a ruler in place I will be set. I am still planning on making a fold down out feed table. I intentionally left the fence long for that reason. After that I want to box in the under section to collect all the saw dust that is getting thrown all around my garage.

Hopefully this might help someone else.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks