Perhaps my question got a bit lost in the "Power Hacksaw" Tread.

So here I go.

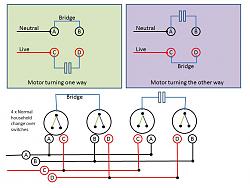

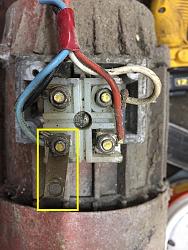

I have a 220V AC induction motor that allows me to change the direction by switching the a "BRIDGE" and the Capacitor internally. There is a sketch in the other tread.

I need some ideas as how to do this with a switch. What type of switch must I ask for and do I need to fit a second capacitor?or has somebody got a cheap DIY method.

I did go through the Electrical/Switches section.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks