I was using the surface plate the other day and accidentally hit my granite square almost knocking it over onto the plate, boy was that scary! If I hadn’t caught the granite square it could have landed on the plate and possibly broken it rendering the square totally useless, that’s when I decided to make a smaller square with a large base.

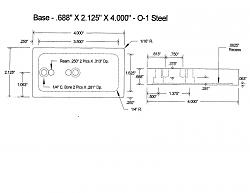

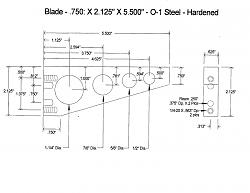

I had a piece of O-1 tool steel that measured 3/4" X 2-1/4” x 16” so I sit down and drew up something that I thought would be sufficient enough for my needs utilizing the materials I had on hand, the base measures 3/4" x 2-1/4” X 4”, and the blade measures 3/4" X 2-1/4” X 5-1/4”, both pieces were precision ground parallel and square on all six sides before any machining was performed.

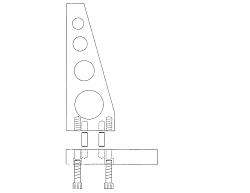

After the machining was performed the two pieces were then hardened, tempered and precision ground all over, they were then assembled with two 1/4" dowel pins and two 1/4" socket head cap screws, the bottom of the base was then reground to insure flatness, the blade was then very carefully reground square to the base within .0001” using my granite square as a master.

I have included various photos of the machining and grinding processes it took to make the square along with a video of its usage, this square will be used in the place of the granite square or the cylinder square, periodically this new square will be checked for stability using the granite square as a master.

As always thanks for looking and happy machining

Doug

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks