Originally Posted by

Eaglewood

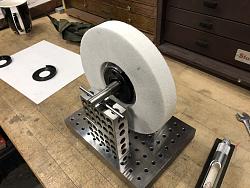

I carefully calculated the difference in masses and sized the flanges accordingly. I made a 3D model in Fusion 360 and found that the cg was almost perfectly on center radially. It was off .002-.003. Off coarse machining tolerance weighs in but I just balanced a 7x1 recessed wheel that was way out of balance and it runs fine.

I found that if I put the wheel on the balance fixture without the weights and mark the heavy point then add the weights perpendicular to that cl it is easier to rotate the weight mass away from the heavy side.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks