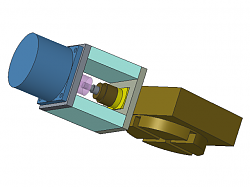

This is a motor mount intended to facilitate using a cheap Harbor Freight rotary table on a CNC machine. I used wood to provide a mounting surface for a stepper motor a set distance away from the existing drive shaft. This allows me to couple to and drive the existing rotary table shaft with a stepper motor. I did have to turn down the rotary table drive shaft with my lathe to fit the flexible coupling I had on hand. I also added a thrust bearing under the drive shaft collar to reduce friction.

I intended to cast the final mount out of aluminum but so far the wood version has performed well for the few times I have used it. I just recently had the thought that it could also be 3d printed. Even if I cast it from aluminum I might 3d Print the pattern so I can make nice draft angles on the pattern for sand casting.

The rotary table I used was the 3" ROTARY TABLE AND CLAMPING KIT - 98077 but it looks like it has been discontinued by Harbor Freight.

Here are pictures of the rotary table mounted to my milling machine in a toolmakers vice which is clamped to the mill table. I added a pillow block on the cantilevered end of the work piece because I was getting too much deflection.

Below is a video of the first item I made using the stepper motor mount with the rotary table. It is a cylindrical lithophane made from a chunk of PVC pipe. The CNC workflow is as follows: Flat G-Code was first generated by Dmap2gcode then the flat g-code was sent through G-Code Ripper to map the flat g-code to the rotary axis.

When the lithophanes are back-lit (with a candle in this case) the image becomes clear.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks