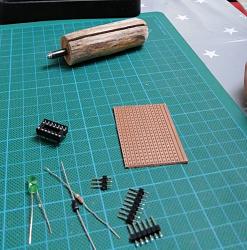

I was making a stripboard project for a magazine and wanted a quick and easy way to make the cuts in the tracks. So I made my own spot face cutter from an old drillbit and a bit of old branch from thee garden.

https://www.workshopshed.com/2020/04/spot-face-cutter/

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks