Hi folks

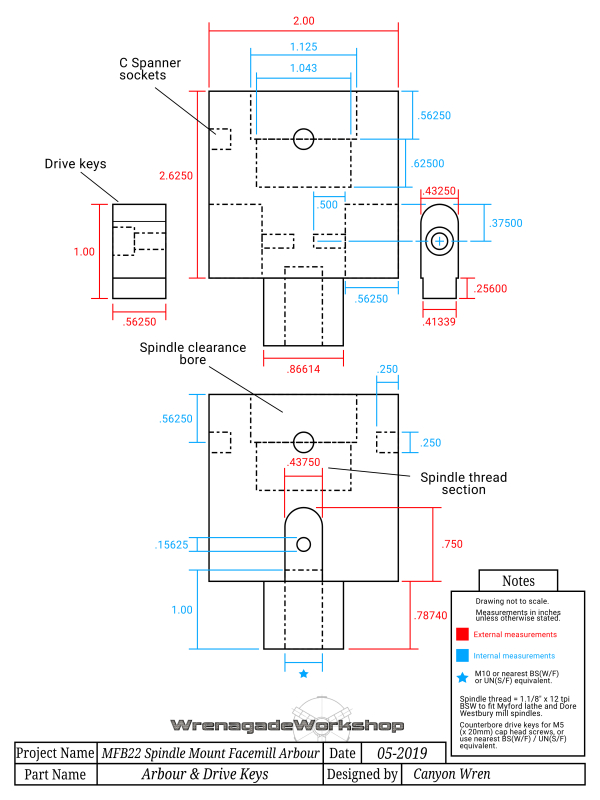

I recently scored myself a brand new Indexa Seiki facemill for very little on eBay and while it was a deal for the money, it didn't come with an arbour, so I figured I would make my own, though I will be deviating just a little from the standard design by omitting the taper shank and after taking measurements from the facemill, I eventually drew up the plan below (see attachment for high res version).

The main reason for the change is that my mill's drawbar is only 9/16" in diameter and rather prone to malformation when attempting to dislodge stubborn MT2 shanks. So instead, I plan to bore and thread the arbour to fit the various spindles I have in my workshop, which are all the same size and tpi.

The advantage of going this route is that the arbour will be concentric to the spindle during the turning operations, once the initail drilling, boring and threading operations have taken place.

Here is part 1

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks