If you're like me there will often be times when you need to put a small diameter item in the chuck to be turned, then shortly afterwards you need to turn something which is much larger. I seem to be forever winding the chuck in and out with the usual T shaped key, and if you're using a large chuck this can be tiring on your wrist after a while.

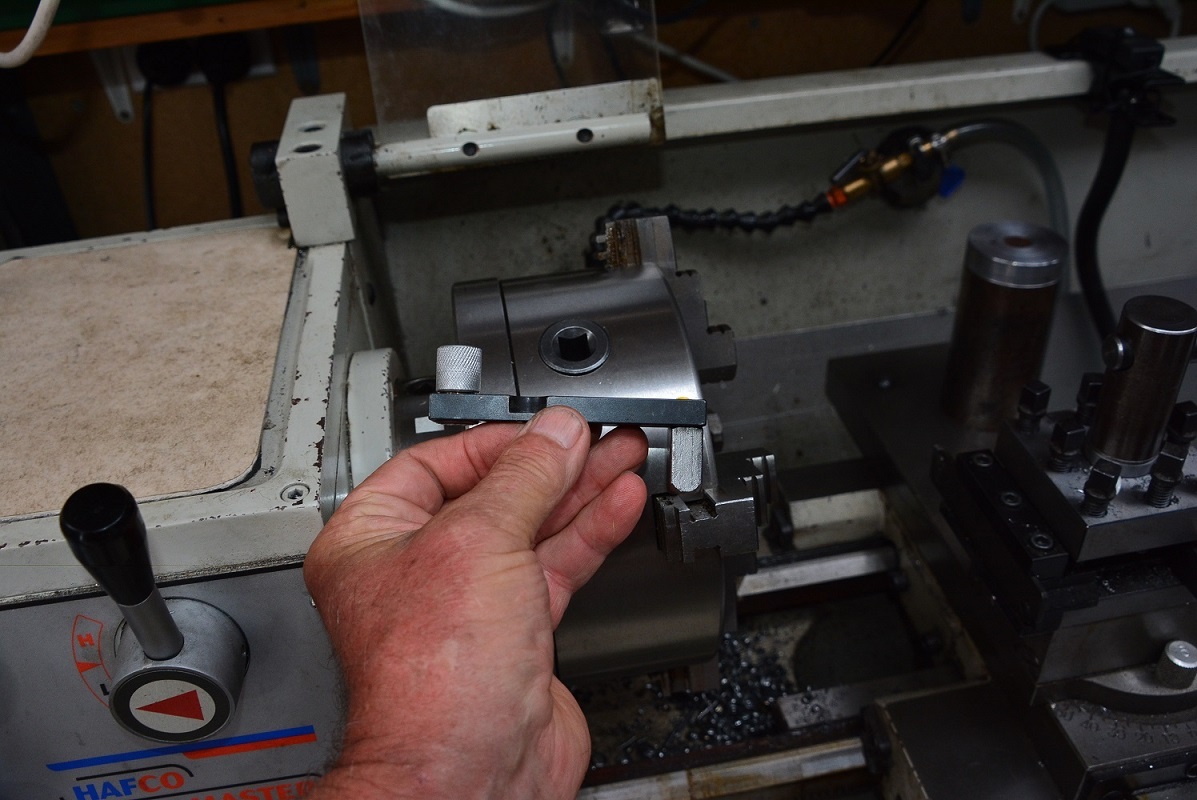

I've made up this key which has a neat fitting square milled from round bar and welded to one end, and a nice fitting knurled sleeve with a bolt through it as a handle on the other end. It works a treat and makes light and quick work of winding the chuck scroll in and out. When you need to tighten the chuck I suggest you use the you use the T key to make sure the item is properly secured.

You will notice the square end which fits into the chuck has been dabbed with nail polish over the weld. I have several chucks all with different size keys and I've made a speedy key for each chuck and used nail polish of different colours to indicate the like sized keys which fit the same chuck.

Ignore the semi circular holes on the handle near my thumb in the 2nd photo, they just happened to be in the scrap bar I used.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks