Valentines bowl for the wife made from an aluminum car wash sign. I over worked the metal to get it to tear for the broken heart and to get all the small hammer blows to show up.. No real meaning just for fun and practice.

My friend cut down an oak tree a few months ago in his back yard so I have a few good chucks of that. These are my first few attempts with a wood turning

from a rotted old bug infested apple tree from my moms yard.

I burned out the middle to dry out the still green oak and just to give some character to the apple wood. Plus I couldn't bore out the middles as deep I would have liked to. There are a few more but I lost the photos somewhere on the internet.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Here is another bowl, this one broke in two pieces while turning, and flew across the garage. I glued it back together any way.

Here is another bowl, this one broke in two pieces while turning, and flew across the garage. I glued it back together any way. this is a balance beam I made for my daughter. It is made from some very old oak 2x4s that a previous occupant of the property I live at left behind. The beam is just resting and not glued in, so it is easy to disassemble. The beam can be positioned on its narrow side for more of a challenge when my daughter (now 3 ) gets older.

this is a balance beam I made for my daughter. It is made from some very old oak 2x4s that a previous occupant of the property I live at left behind. The beam is just resting and not glued in, so it is easy to disassemble. The beam can be positioned on its narrow side for more of a challenge when my daughter (now 3 ) gets older.

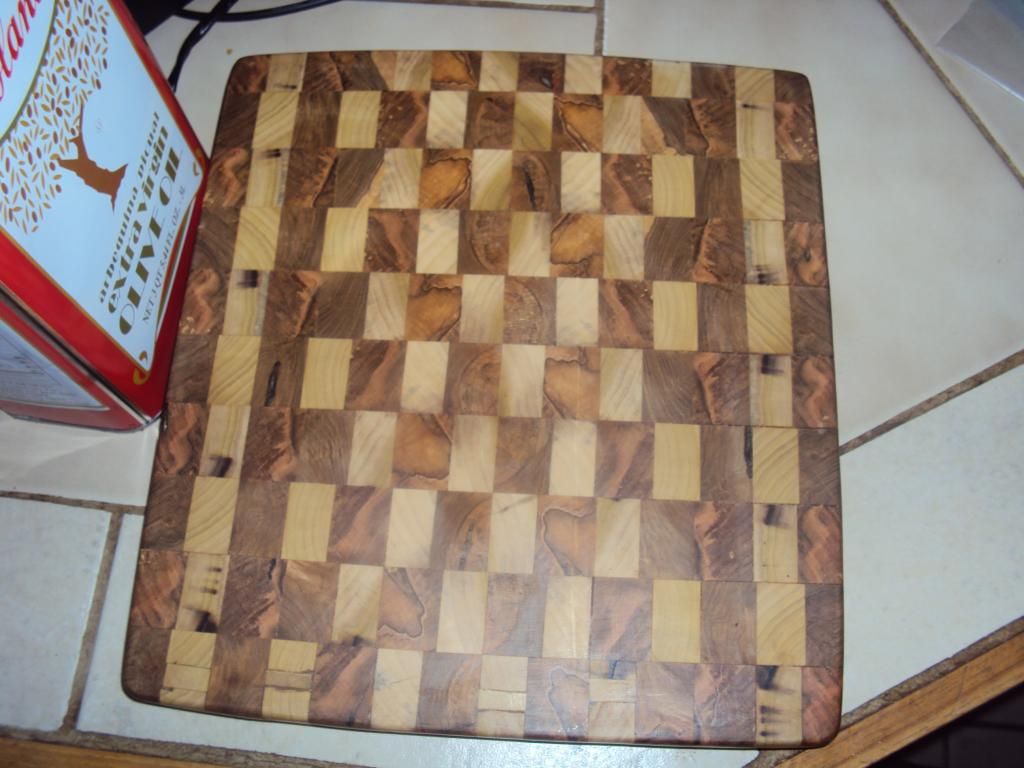

this is a cutting board i made from some pallet wood.

this is a cutting board i made from some pallet wood.

Bookmarks