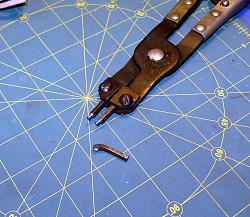

While I was servicing one of my routers it came to my attention that I could not find one of my snap ring tip kits. While I was sitting on the throne it dawned on me that I have a lot of hex wrenches. I know right where they are too. So out came the cut off wheel, and into my mill chuck pieces of hex wrench went. The rest of the making is pretty straight forward. When the tip fits it's done. I finished them up with some tool room stones while the tips were spinning in the chuck. They worked great too.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks