I needed to make thousands of small 12BA and 10BA Coachbolts for the models I make.

I started to make them on a Unimat 3 lathe using a cutting tool, after many mistakes and it taking a rather long time to make each miniature Coachbolt one at a time, I realized I needed to make the process much quicker and easier.

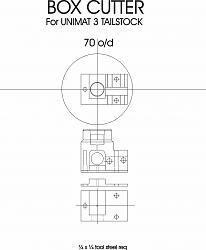

I have the book by Stan Bray, called MAKING SMALL WORKSHOP TOOLS, on page 67,68,69 and 70 are drawings for a simple box tool with a taper on it, for fitting into the tailstock of a lathe.

Using these drawings as a guide and with a bit of head scratching and a few false starts, I eventually came up with this lot.

It just screws onto the tailstock of the U3 lathe, once the tooltip is set for the correct size shaft for the coachbolt I require, then it's into it and I can make thousands of whatever length coachbolts I need, just set and forget.

The Unimat 3 is very good for this, just push the tailstock up to the Tobin Bronze sticking out of the chuck and then one turn of the tailstock is one millimeter, if I need a ten mill bolt, then turn the handle 10 times, simple as, eh.

Tobin Bronze is a heck of a lot cheaper than brass and is far stronger than brass of the same small diameter, using bronze you will get far fewer breakages than if you used brass for the miniature coachbolts.

Threading the miniature coachbolts is dead easy, I just used a broken screwdriver and drilled a hole into the main pulley, insert this handle and crank away as many times as you want. The bronze does not grab like brass and it is very easy to hold the die in your fingers when doing 10BA or 12BA.

Used the K.I.S.S. principle here, far fewer things to go wrong, just screw on what sized cutter for the different sized coachbolts I need and away you go.

The drawing can be adapted to whatever lathe you might want it to fit.

Psst, K.I.S.S. = Keep It Simple Stupid

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks