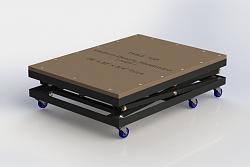

I made this Small Workshop Lift-Table a few years ago and use it almost daily.

The table is raised and lowered by using a 1/2 horse drill with a socket attachment to turn a nut welded to the end of an ACME threaded rod that goes through another ACME Nut.

As many of you know, ACME thread is considered a ‘Trapezoidal Thread Form” used for simple Leadscrews because the thread’s tooth shape wears better and allows it to carry a greater load much easier than common threaded ‘ready rod‘ ... However, you can use normal threaded rod but it will take a more hand drill torq to raise and lower the lift.

Depending on the direction the threaded rod is turned with the hand drill the lift lowers or raises.

The Lift-Table can be lowered down close to the floor (I store mine under my Jeep) or raised to over 5 feet …

Photo Shows the Small Workshop Lift-Table Raised to 54″

When I built this Small Lift-Table didn’t think I would use it as much as I do; however, it has turned out to be a wonderful ‘Back-Saver’ and I just used it again recently to transfer a heavy Sand Blasting Cabinet full of Abrasive Media from a higher table to the new lower STAND I fabricated out of leftover ‘scrap’ metal.

There are some simple Mechanical Drawings with Dimensions for building the lift table in Adobe Acrobat PDF format that you can download from the 'Attachments' area below the example Video Link ~ DIY Workshop Lift Table - CTER's library

CHEERS!! :o

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

unlike yours.

unlike yours.

Bookmarks