Thanks Alan, Sketchup files would be great!

A little late in chiming in on this but powered bag trolleys can range from .20 to .45 HP some are gear reduction others are low RPM high torque

Golf carts proper can range from 36v with 3.75 HP 3100 RPM to 48 V 12 HP with 1200 RPM high torque low RPM wound.

A while back I dismantled an old walk behind floor scrubber mainly for the 6 Trogen 105 6 v batteries but I kept the 3 motors and drive differential for future projects the 2 scrubber motors were gear reduction 4 HP 36V while the drive motor also had a electric brake as well I figured that one will become a milling spindle attachment for one of my Leblond lathes Probably the 26 x 60 with gap bed

Never try to tell me it can't be done

When I have to paint I use KBS products

Alan, nice one as usual.

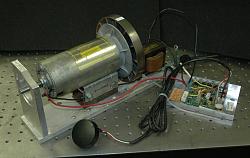

My toolpost grinder should more accurately be called a toolpost spindle, as you call yours, because it has an MT2 taper which allows the fitting of many different working ends, grinding wheel, internal mounted grinding bobs, drill chuck, ER chuck etc.

Click pix for full size.

I use a 2 HP DC motor from a treadmill with my own controller for speed regulation.

Last edited by tonyfoale; Dec 20, 2017 at 02:50 PM. Reason: spelling

drivermark (Dec 21, 2017), EnginePaul (Dec 23, 2017), Home-PC (Nov 8, 2022), Jon (Dec 20, 2017), olderdan (Dec 20, 2017)

Nice job Tony,

That was a year old post of mine and now superseded by my geared milling spindle but I still use it for some jobs.

Your version is a lot more substantial, BTW how do you guys get all those treadmill motors, cant find them in the UK I think they must all be powering rocking horses.

Merry Christmas.

Alan,

I lived in the US for 3 years and over there they have two great institutions. Weekend yard sales and Craigs list. If you can't find something on one you'll find it on another. People buy treadmills with good intentions of exercising but soon get tired of it and decide that they need the space back.

I bought a treadmill whilst there for $10 or similar and when I left there was no way that I wasn't taking the motor. I also found a couple more motors before leaving. Many people use the controller from the treadmills but they have all sorts of built in safety features which make those controllers less suitable for use on machine tools. For example it is usual to have delays programmed in as well as slow start and slow stop features to avoid throwing you off the end of the treadmill. That is why I make my own controllers. My first use for one was as an ignition system tester.

Click pix for full size

The pic on the left also shows the treadmill controller, it was on this device that I discovered the peculiarities of these controllers. The delays made it a pain to set "exact" RPM.

I'll try to remember to make and scan a sketch. I build simple circuits like that without drawing them first. There are several methods that you can use, the simplest and also most expensive being a Variac and rectifier. Pure electronic solutions are much cheaper and the simplest of those is a thyristor circuit followed by a full wave rectifier. A more elegant way would be using PWM (pulse width modulation), this can be done by generating the PWM signal with something like an Arduino followed by a MOSFET for the power switching.

I use the thyristor method just like light dimmers, although they don't need the following rectifier.

That's all way over my head Tony. Since I don't know a watt from an ohm I have a real problem following what you're saying. In the not so distant past I would have asked for a diagram and parts list referring to Radio Shack part numbers, although I did find they still have an online store with a couple of those parts you mentioned listed

There are currently 1 users browsing this thread. (0 members and 1 guests)

Bookmarks