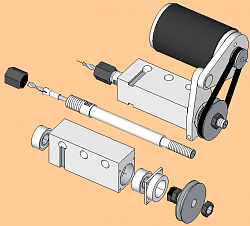

¼ inch milling/drilling/grinding spindle.

This is a universal medium duty spindle that has proved very useful over the years.

The body is alloy and is accurately machined to be square, parallel and bored central to the two mounting faces, this is important to allow for various set ups.

The spindle is tool steel and bored for Crawford spit collets simply because I had them in three sizes of imperial and two in metric, and can accommodate a drill chuck if needed.

Bearings are 28x12x8 rubber sealed.

Power is a 12volt DC motor from a golf cart and run through a cheap PWM speed controller, drive belt is from a sewing machine which was a temporary measure but has proved up to the task.

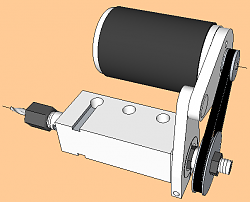

This will just about push a ¼ drill into steel without a pilot hole (not something I would normally do) but you have to find the limits don’t you.

It happily copes with end mills and a mini fly cutter with a ½ inch sweep and I have used it for grinding using mounted point wheels, this has been useful for truing worn chuck jaws etc.

The benefit of taking care in machining the main body is that with a dedicated spacer block it can be mounted either way up exactly on the lathe centre line.

This gets used a lot in my vertical milling attachment of which more later (pictured for now).

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks