Here are three fixtures I use to hold small parts for machining additional features. They use different kinds of home made clamps.

The hinged clamp is for holding screws on the rocker slide for slotting on my lathe. It has easy-to-make replaceable jaws so I can clamp different diameters up to about 3/8Ē.

It doesnít lock and just works by leverage by feeding the slide upwards with one hand and pressing the top jaw down with the other.

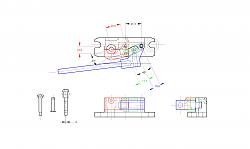

The just-completed sideways toggle clamp is for holding round parts on a mill or drill press. It has the same kind of replaceable jaws as the slotting clamp.

It works either with the regular handle, or with a foot pedal by hooking up the bicycle brake cable and engaging the torsion spring. The clamp has about 1/32Ē range of adjustment by rotating the eccentric toggle pivot pin thatís farthest to the right.

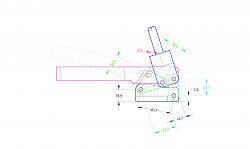

The upright toggle clamp goes on the sliding table on my router. The angle iron base has a vertical fence for attaching temporary wooden fixtures, and this mounts to a slotted base plate that I tapped in lots of places.

The clamp has a couple extra links in order to apply downward pressure along with the usual sideways force to position parts more consistently, as well as to keep them in place during upward plunge cuts, also operated by a foot pedal with a cable.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks