Due to my Milling Machine being so small I had to move the vice to get the 20mm Drill in and out of the chuck.

I needed a 21mm hole that needed to be a tight fit for my 12mm linear bearings. The 20mm drill drilled a 20.5mm hole so not a lot for me to play with to get the hole to a 20.95mm press fit.

I had a small dial gauge that I wanted to use as an edge finder but never used as I got a very inexpensive commercial variety.

A quick search on this forum and even on Google did not reveal anything. I hate to reinvent the wheel.

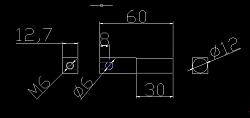

So I quickly fabricated this holder. Basically 60mm of 1/2" square bar from the scrap bin, Turned the one side down to 12mm to fit into the boring Head. Here I used my socket adapter as I do not have a 4 jaw chuck.

The other side a 6mm hole to mount the gauge and an M6 in the bottom to clamp it all secure.

Worked like a charm.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks