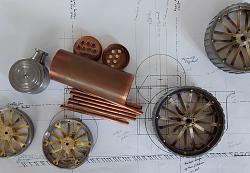

I've literally been back to the drawing board for the miniature traction engine to work out the detailed design of the next few parts.

The firebox is a challenge, but feels like I have a reasonable way forward.

The engine feels a bit more tricky, plan was to create a bracket on the boiler that is brazed in place and the cylinder bolts to it, just not sure if I should use brass for this due to corrosion?

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks