Just made the crosshead guide or trunk guide.

Not quite a scale crosshead for a Burrell, but I wanted something that works at this scale. I might still put it back in the lathe to tweak a couple of the dimensions to make it more compact.

Just made the crosshead guide or trunk guide.

Not quite a scale crosshead for a Burrell, but I wanted something that works at this scale. I might still put it back in the lathe to tweak a couple of the dimensions to make it more compact.

The crosshead guide has been concerning me, so I bolted it to the cylinder. The marking out for the bolts took some time to think about and achieve.

The crosshead guide in context actually looks ok, I might thin down the wall thickness. 1.5mm could go down to 1.2mm

Now onto the crankshaft. If you remember my earlier design discussions I was struggling to see a way to getting a 6mm throw and hence 12mm stroke. Well, there are a few things that help this: 1. offset of the cylinder and curvature of the firebox 2. ability to lift the bearing blocks slightly 3. two-piece crankshaft and hence single piece conrod big-end.

So here is a sketch of the crankshaft:

I assembled and silver soldered this with a single piece main shaft. That made it easy to align everything and machine surfaces. One of the last actions was to then split this main shaft and machine back to the internal web faces.

Just to prove it still splits into two:

EnginePaul (Jul 27, 2021), Paul Jones (Jul 28, 2021)

I've lifted the bearing blocks 1.5mm and I now have clearance to the firebox

it's tight, but that was always going to be a challenge with this 1/20th scale Burrell.

The cylinder saddle is firstly being bolted to the boiler, thus ensuring alignment before I silver solder.

The homemade phosphor bronze bolts are to avoid the possibility of dezincification of brass parts that are permanently fixed to the boiler.

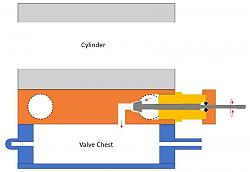

I machined the Burrell valve chest out of a piece of solid brass and then made the centre valve shaft bearings as one.

Once this was silver soldered together I then machined out the centre.

Hopefully the bearings for the shaft are still aligned.

editor@glue-it.com (Aug 30, 2021)

The steam valve in this 1/20th scale engine is challenging and so I thought I would talk through the options:

Having machined the valve chest and cover I needed to create the nameplate. At first I thought it should be just a capital N for me, but in the end I decided it should be a proper Charles Burrell nameplate.

The first one was OK:

but I thought I should make a few more and select the best.

So, another 4 and I think the best one is this one:

The black is just permanent marker for now to give some contrast so I can see if it is ok. In the end it will be painted.

I had a lot to live up to as my dad made this clock and etched the face over 30 years ago. He created the mask using a UV sensitive film and creating a photographic plate (in darkroom he had built into the roof space of my childhood home).

PS: this clock keeps good time.

rlm98253 (Sep 3, 2021)

Looking in more detail at the steam valve design. The schematic looks reasonably simple. However, I've been looking at a number of references to try and improve my background knowledge of steam valve design.

There are currently 5 users browsing this thread. (0 members and 5 guests)

Bookmarks