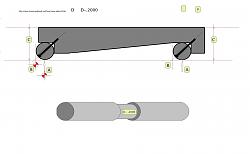

Mechanical Sine functions depend on two rolls a known distance apart, 5" and 10" are common but any distance works. With gauge blocks stacked under the 'rear' pin, it elevates the plate a specific amount, by a simple calculation. If pivot and rear are parallel in two planes, accuracy is assured. Quality sine plates have two surfaces for gauge blocks, one being .1000 deeper. That accommodates block sets with .1000 minimum thickness, using .1001 will create the incline.

https://en.wikipedia.org/wiki/Sine_bar

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks