Accurately measuring bores is one of the more difficult tasks to master. Tools like split-ball and telescoping gages demand the development of a fine "touch" to get repeatable pressure on the instrument. George Britnell, a master machinist and model builder, designed a tool to essentially remove the "touch" requirement from the operation. This post describes my version of his tool.

The tool consists of a bar with a 0.0001" DTI secured to one end. On this bar is a a moving arm whose position can be minutely adjusted with a screw. In use, the indicator on the end of the bar is applied to one side of the bore and the screw is used to extend the DTI until it reads a near mid-range value. Said reading is noted and the gage removed from the bore. A micrometer is placed across the point and DTI and adjusted until the DTI reading matches the noted reading. At this point the micrometer is applying the same pressure as the gage experienced in the bore and hence the reading it shows is the diameter of the bore.

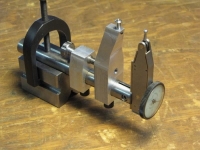

The gage I made looks like this...

and a side view of the gage.

This tool cried out to me for a vernier fine adjustment and, feeling the need to personalize the project, I added one. It acts similar to the sort used on beam compasses but, instead of a simple threaded shaft uses a differential screw.

As is apparent in the next picture, the differential screw is threaded with two different threads. The body that threads into the vernier guide is 1/4-40 and the end which threads into the movable arm is threaded 10-32.

With this arrangement, one turn of the vernier adjustment knob will move the movable arm by:

1/32 - 1/40 = 1/160 = 0.00625"

the equivalent of a 160 tpi thread. With six notches on the knob, a one notch movement is very close to one thousandth of an inch movement.

The next photo shows the dovetail that secures the DTI in the end of the rod. To make it, I slotted with a 3/16" endmill to the correct depth and then cut the dovetail with a 1/4" dovetail cutter that I purchased from Brownells, the gunsmith suppliers in Iowa. Such tiny cutters are used to cut the dovetails used to secure the (adjustable) front sight on some types of firearms.

Aside: As made, the adjusting screw is backwards. A clockwise turn of the screw will move the movable arm toward rather than away from the vernier guide. Were the 32 and 40 tpi sections reversed, this would be rectified but I was using dies and wanted a one piece screw so accepted the reversed movement which doesn't annoy me anyway. However, be warned if you make your own differential screws - think it through first.

If you want help with the mathematics of designing differential screws, there's a program on my page titled, surprisingly, DIFFTHRD that will be of assistance.]

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks