Why make anything at all when you probably have the ideal gadget already.

Namely a planer gauge (subject of much recent discussion) used with the same thumbnail method or slide a small parallel over the tool, once set to the exact centre line of your lathe you can reset it with a mike if used for something else. I have tried using an LED contact method but for me it is not worth the bother.

We all have our favorite methods and that’s just fine if it works.

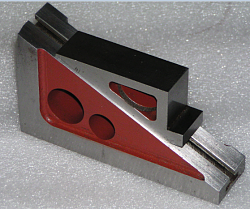

Here’s one I made earlier as they say (about thirty years ago).

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks