Having gone into isolation about a week ago, I've been in the rare position of being able to catch up on my project "to do" list. One such project was to make a side drill for my sister in laws partner as a gift.

He's a really decent guy and very creative with wood, so I felt a tool such as this would have great potential in his hands.

Took about three days of fiddling and fettling in total but the only thing I actually paid for to make this happen was a couple welding rods and the drill chuck, all but the brass bushing were material repurposed from my scrap hoard, the brass was a momentum I was given after my mother in law passed away a couple years ago, so I thought it would it be a fitting to use it in this project..

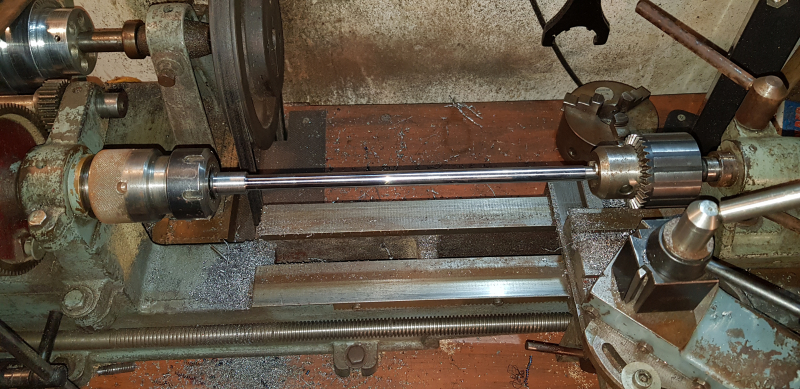

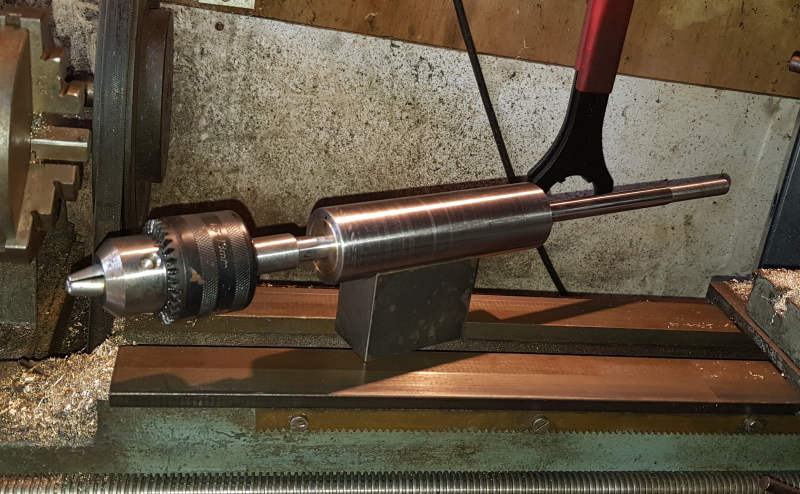

Here I've modified the mag drill adaptor that came with the chuck for a light press fit and put it back in the lathe while the green goo dries.

I'd already made the spindle housing and riser a fair while ago and documentation wasn't something I did a lot of back then. I also didn't take pics while making the bushings as it was late and simply forgot.

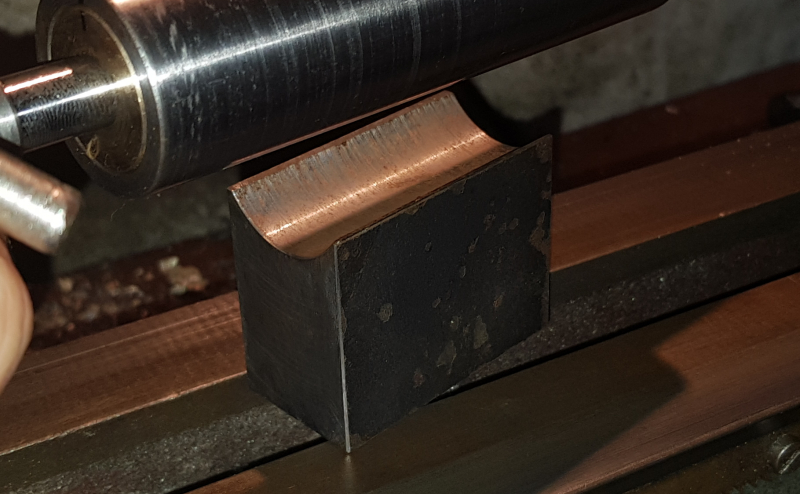

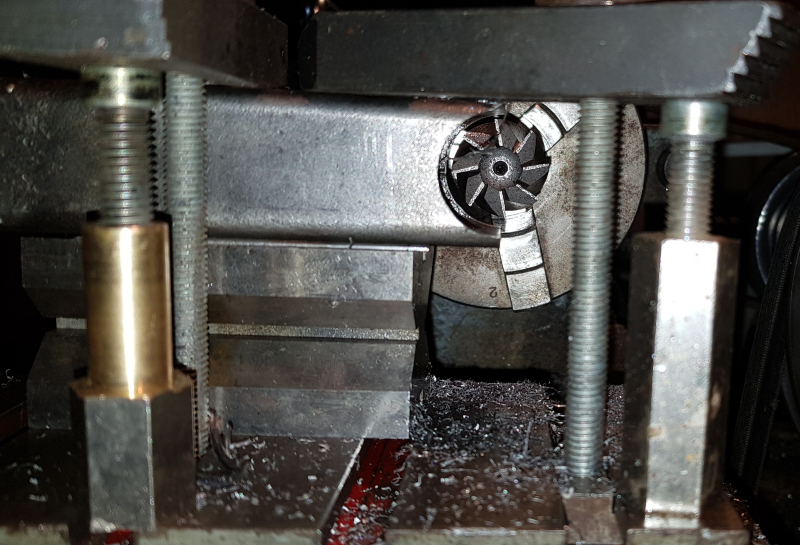

I notched the radial arm using a 1" milling cutter and plunged it to depth. Side milling with a cutter that size isn't something my little lathe can handle but plunge milling went without a hitch.

Here it is put togather. Ther bore shrank a tiny bit but this was fortunate as it was slightly oversize before welding. It's ever so slightly tight but theres no play in any direction and it turns true, so I'm happy with the results. Materials are pretty heavy duty, so it should be resistant to vibrations and last him a good while.

Just need to surprise him with it now, thanks for looking

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks